PRODUCT FEATURES

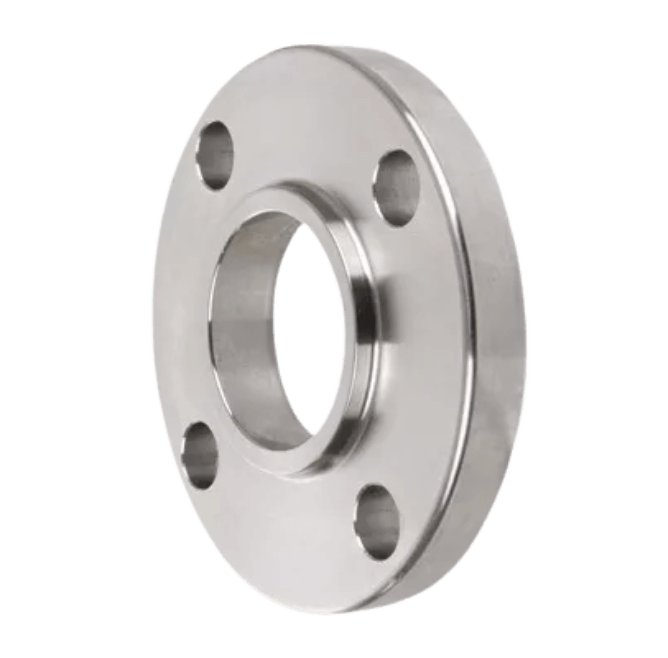

Slip on Flange Manufacturer to Rocket Your Business

PRODUCTS

Proud To Offer A Wide Variety Of Flanges

If you are looking for something specific that isn’t listed on our website yet, just contact us today!

ABOUT US

Who Is Oflange.com

oflange.com have seen that today there are also many flange companies in China & internationally. However, their solutions were still stuck a few years ago.

In fact, we have been upgraded in recent years, and oflange.com hope our smart and flexible solutions can inject fresh blood into this market.

PARTNER

Who Trust Us

BUYER’S GUIDE

Slip-On Flange: The Ultimate Guide

A slip-on flange (SOF) is a type of flange that is bolted to the end of a pipe. It has an annular groove in it which accepts a gasket. The SOF is then bolted to another flange, usually on a valve or pump. This forms a seal between the two flanges and allows fluid to flow through the pipe.

The slip-on flange is a type of blind flange. This means that it does not have any holes in it for bolts. The bolt holes are drilled in the mating flange, which then screws onto the SOF.

Slip-on flanges are available in a wide range of sizes and pressure ratings. They can be made from a variety of materials, including carbon steel, stainless steel, and alloy steel.

Table of contents

1. Uses of a Slip-on Flange

What is a slip-on flange? Flanges are usually used for several projects in a number of industries. Slip-on flanges specifically are used in joining two pipes together and providing a seal between the two flanges. There are many different types of slip-on flanges, but they all essentially do the same thing.

Slip-on flanges are used in a wide variety of applications, such as:

- Joining two pipes together

- Attaching ductwork to an air handler

- Repairing a leaky flange

- Repairing a damaged pipe

- Creating a custom flange

- Connecting a pipe to a valve or pump

- Connecting a pipe to a piece of equipment

- Creating a seal between two flanges

- Converting a threaded connection to a flanged connection

2. Installation of Slip-on Flange

The steps for installing a slip-on welding neck flange are simple and can be completed by anyone with basic mechanical knowledge. The procedure for installing a slip-on flange is as follows:

Step#1 Place the Slip-On Flange on the End of the Pipe

The slip-on welding neck flanges should be placed on the end of the pipe that will be connected to the mating weld neck flange. The annular groove in the slip-on flange welding should face the mating flange.

Step#2 Align the Bolt Holes of the Slip-On Flange With the Bolt Holes of the Other Flange

The bolt holes in the stainless steel slip-on flanges should be aligned with the bolt holes in the mating flange to ensure a proper seal.

Step#3 Insert Bolts Through the Bolt Holes and Tighten Them

Bolts should be inserted through the bolt holes and tightened to secure the slip flange dimensions in place so that it does not move during operation.

Step#4 Install a Gasket in the Annular Groove of the Slip-On Flange

A gasket should be installed in the annular groove of the slip-on pipe flange. The gasketshould be made of a material that is compatible with the fluid that will be flowing through the pipe.

Step#5 Test for Leaks

Once the slip-on blind flange is installed, it should be tested for leaks. To do this, apply pressure to the slip-on flange and look for any leaks around the bolt holes. If a leak is detected, the slip-on flange can be tightened or replaced.

If you follow these steps, you should be able to install a flange without difficulty. Make sure to have a look at our selection at Oflange for slip-on pipe flanges. We provide a number of sizes and designs, so you’ll be able to discover the ideal one for your application.

To know more about how to install or fit the slip on flange, check out this video.

3. Sizes of Slip-on Flanges

There are a variety of slip-on flange sizes available on the market. The most common slip-on flange sizes are 4-inch slip on flange and 8-inch slip on flange. However, there are also a variety of other slip-on flange sizes available, such as 6-inch slip on flange and 16-inch slip-on flange dimensions.

These are the slip flange chart that is available in a wide range of sizes.

| No. | Sizes |

|---|---|

| 1 | ½” 15 slip-on flanges |

| 2 | ¾” 20 slip-on flanges |

| 3 | 11⁄16” to 13⁄16” 25 slip-on flanges |

| 4 | 13⁄16” to 15⁄16” 30 slip-on flanges |

| 5 | 15⁄16” to 18” 35 slip-on flanges |

| 6 | 18” and larger 40 slip-on flanges |

The size of the slip-on flange is determined by the steel pipe size that it will be used with. The slip-on flange must be the same size as the pipe to ensure a proper seal.

4. How Do I Know If My Pipe Size Is Compatible With a Slip-on Flange Size?

Follow the instructions below to find out whether your pipe size is compatible.

Measure the Outside Diameter Of the Pipe

The easiest way to determine if a slip-on flange is a correct size for your pipe is to measure the outside diameter of the pipe. The slip-on flange must be the same size as the pipe to ensure a proper seal.

To measure the outside diameter of the pipe, you will need a tape measure or ruler. Place the tape measure or ruler at the end of the pipe and extend it to the other end of the pipe. The OD of the pipe should be equal to the slip-on flange size. For example, if you have a ½” pipe, you will need a ½” slip-on flange.

Make a mark at the point where the tape measure or ruler meets the end of the pipe. Measure the distance between the two marks to determine the outside diameter of the pipe.

Consult a Slip-On Flange Size Chart

Another way to determine the compatibility of an ms slip-on flange with a pipe is to consult a slip-on flange size chart. These charts list the slip-on flange sizes that are available and the corresponding pipe sizes.

You can also use a slip-on flange size calculator to determine the correct slip-on flange size for your pipe.

If you’re not sure which slip-on flange standard size to choose, our experts at Oflange can help. We have a wide selection of flanges slip-on and can provide recommendations for your specific application.

5. Benefits of Using a Slip-on Flange

There are many benefits to using a slip-on flange, such as:

Easier To Align

Slip-on flanges are easier to align than other types of flanges, such as welding flanges. This makes them ideal for use in low-temperature environments.

Prevent Leakage

Slip-on flanges create a seal between two pipes to prevent leakage. This is especially important in applications where fluids are being transported under high pressure.

Reduce Cost

Slip-on flanges are less expensive than other types of flanges, such as welding flanges. This makes them an ideal choice for use in budget-conscious applications.

Easy to Install

Slip-on flanges are easy to install and can be done by anyone with basic mechanical knowledge. This makes them ideal for use in applications where time is of the essence.

Cut Pipe’s Precision

The accurate cut of pipe slip-on flange can maintain the pipe’s precision and do not affect slip-on flanges installation.

Compatibility

Slip-on flanges are compatible with a wide range of pipe sizes, making them an ideal choice for many different applications.

Installation at a Low Cost

Slip-on flange installation does not require special skills or training and can be done by anyone with basic mechanical knowledge. This makes slip-on flanges an ideal choice for many different applications.

Reduce Maintenance

Slip-on flanges are less likely to leak than other types of flanges, making them an ideal choice for applications that require minimal maintenance.

Sufficient Strength

Slip-on flanges provide sufficient strength to withstand the pressure of fluids flowing through them. This makes them ideal for use in high-pressure applications.

Low Hub on the Slip-On Flanges

The slip-on flange has a low hub, which makes it easier to align the bolt holes of the slip-on flange with the bolt holes of the mating flange. This prevents leakage around the bolt holes and creates a stronger seal.

Slip-on flanges are an essential part of many piping systems. If you are in need of a slip-on flange, be sure to consult a professional to ensure that you select the correct size and pressure rating for your application.

6. Potential Problems With Using a Slip-on Flange and Its Solution

There are a few potential problems that can occur when using slip-on flanges:

Incorrect Size

If you select the incorrect size slip-on flange for your pipe, it can be difficult to get a proper seal and the flange may not fit properly. This can lead to leakage and other problems.

Incorrect Pressure Rating

If you select a slip-on flange with a pressure rating that is too low for your application, it can lead to failure of the slip-on flange. Be sure to select a slip-on flange with a pressure rating that is appropriate for your application.

Improper Alignment

If the slip-on flange is not properly aligned with the mating flange, it can lead to leakage and other problems. Make sure that the slip-on flange is aligned correctly before tightening the bolts.

Gasket May Not Seal Properly

Another potential problem with using a slip-on flange is that the gasket may not seal properly if it is not installed correctly. If you are having trouble installing the gasket, be sure to consult a professional for assistance.

These are just a few of the potential problems that can occur when using slip-on flanges. If you are having problems with your slip-on flange, be sure to contact us at Oflange to consult a professional for assistance. A qualified technician will be able to help you troubleshoot the problem and find a solution.

7. Cost of a Slip-on Flange

The approximate cost of a slip-on flange ranges from $50 to $200, depending on the size and pressure rating of the slip-on flange.

If you are in need of a slip-on flange, be sure to consult a professional to ensure that you select the correct size and pressure rating for your application. This will help prevent potential problems down the road and ensure that your piping system functions properly.

It’s best to call us at Oflange directly if you need a precise quotation. We can assist you in selecting the appropriate flange face for your needs and provide you with an accurate cost estimate.

8. Tools Required To Install a Slip-On Flange Properly

In order to install a slip-on flange properly, you will need the following tools:

Wrenches (Socket Wrench and Open-Ended Wrench)

This tool is used to hold the slip-on flange in place while you are tightening the bolts.

Teflon Tape or Pipe Dope

This is used to create a seal between the slip-on flange and the mating flange.

Hammer

This is used to help align the slip-on flange with the mating lap joint flanges.

Measuring Tape or Ruler

This is used to measure the distance between the slip-on flange and the mating flange.

Torque Wrench

This tool is used to ensure that the slip-on flange is properly tightened.

Pipe Cutter or Hacksaw

This tool is used to cut the pipe to the correct length.

Slip-On Flange Gasket

This component is used to seal the slip-on flange to the pipe.

Bolt

These components are used to secure the slip-on flange to the pipe.

Nut

Nuts are used to secure the bolts to the slip-on flange.

Washer

This component is used to prevent the bolt from damaging the slip-on flange.

Bolt Hole Template (If Needed)

This tool is used to help align the bolt holes of the slip-on flange with the bolt holes of the mating flange.

9. Final Words

Our Slip-On Flanges are made with a unique design that makes them quick and easy to install, without the need for welding or bolting. This means you can save time and money on your next project.

Our Slip-On Flanges are also made from high-quality materials, so you can be sure they will last for years to come. Plus, our team is available 24/7 to help with any questions or concerns you may have about our products.

Contact us today to learn more about our Slip-On Flanges!