PRODUCT FEATURES

ANSI Flange Manufacturer to Rocket Your Business

PRODUCTS

Proud To Offer A Wide Variety Of Flanges

If you are looking for something specific that isn’t listed on our website yet, just contact us today!

ABOUT US

Who Is Oflange.com

oflange.com have seen that today there are also many flange companies in China & internationally. However, their solutions were still stuck a few years ago.

In fact, we have been upgraded in recent years, and oflange.com hope our smart and flexible solutions can inject fresh blood into this market.

PARTNER

Who Trust Us

BUYER’S GUIDE

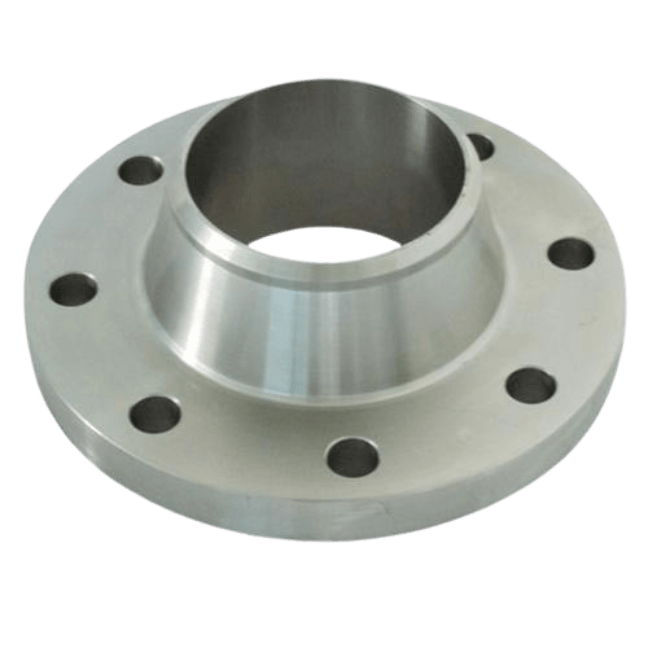

ANSI Flange

ANSI Flange is a durable, versatile, and easy-to-use flanged fittings that is perfect for any piping application. This flange is made of high-quality materials and is built to last.

It is also easy to use, making it the perfect choice for any project. The ANSI flange is a versatile, long-lasting, and reliable product. It comes in three different sizes to fit all your needs.

The ANSI flange is made of high-quality materials and is perfect for any project. This product is also backed by a warranty.

Table of contents

1. ANSI Flange Definition and Its Uses

ANSI Flanges are fittings that are used to join two pipes together. ANSI flanges have a raised face on one side which allows for a bolted connection. ANSI flanges come in a variety of sizes and are made from different materials.

ANSI flanges are commonly used by mechanical engineers in the construction of pipelines and the petrochemical industry. There are two types of ANSI flanges:

- Slip-on ANSI Flanges – have a raised face on one side and a smooth nominal pipe size bore on the other.

- Weld Neck ANSI Flanges – welding neck flanges have a raised face on both sides and a threaded bore.

ANSI flanges chart pdf are manufactured to meet specific standards set by the American government agencies. ANSI standards are used in a variety of applications, including:

- Pipeline Construction

- Petrochemical Industry

- HVAC Systems

- Plumbing Systems

- Shipbuilding

- Aerospace Industry

2. The Benefits of Using ANSI Flange

The ANSI flange is a type of flange that is used in many industries. It is known for its high quality and durability. There are many benefits to using American National Standards Institute flanges. Some of the benefits include:

Durable

ANSI flanges are strong and durable. They can withstand high pressure and the diameter of the bolt are resistant to blind flange corrosion.

Easy to Install

ANSI flanges are easy to install and use. They are compatible with a variety of piping systems and can be used in both pressure and non-pressure applications.

Reliable

ANSI blind flanges are reliable and efficient. They provide a tight seal and ensure the smooth flow of liquids and gases.

Cost-Effective

ANSI flanges are cost-effective. They are less expensive than other types of flanges and are a more cost-effective option in the long run.

Easy to Maintain

ANSI flanges are easy to maintain. They do not require frequent cleaning or lubrication and can be easily repaired if damaged.

Overall, ANSI flanges are a superior choice for industrial applications. They are strong, durable, and reliable, and provide a tight seal that ensures the smooth flow of liquids and gases.

3. Manufacturing Process of ANSI Flange

The ANSI flange is a type of flange that is commonly used in the American Organization. It is specifically designed to meet the requirements of the American National Standards Institute. The ANSI flange is made up of two parts:

- Hub – the hub is the part of the flange that is attached to the pipe.

- Flange – the flange is the part that attaches to the pipe fittings.

There are a few steps that are involved in the manufacturing process of ANSI flanges.

Step #1 Cut the Metal Into the Desired Share

First, the blanks are created by using a cutting machine. This machine uses a high-pressure water jet to cut the metal into the desired shape.

Step #2 Form the Blanks Into Their Final Shape

The blanks are then formed into their final shape using a stamping machine. This machine applies pressure-temperature ratings to the blank to create the desired shape.

Step #3 Finish by Using a Grinding Machine

Finally, the ANSI flange is finished by using a grinding machine. This machine smooths out any rough edges or blemishes on the surface of the flange.

By following these steps, ANSI flanges can be manufactured quickly and efficiently. If you are interested in purchasing flanges in international entities, don’t hesitate to contact Oflange for assistance. They will be able to provide you with all the information you need to make an informed decision.

4. The Difference Between ANSI Flange vs DIN Flange

There are a few key differences between ANSI flanges and DIN flanges, and these differences are specified on the following:

| Size | The most obvious difference is the size. ANSI b16.5 flanges are typically larger than DIN flanges. ANSI flanges also have a slightly different shape, and the bolt holes are angled differently. |

| Location | It has a larger diameter than the DIN flange, and the bolt holes are angled differently. DIN flange has a smaller diameter than the ANSI flange, and the bolt holes are angled differently. |

| Diameter | It has a larger diameter than the DIN flange, and the bolt holes are angled differently. DIN flange has a smaller diameter than the ANSI flange, and the bolt holes are angled differently. |

Which flange you choose depends on your needs. If you need a larger flange, then the ANSI flange is a good option. If you need a smaller flange, then the DIN flange is a good option.

5. ANSI Flange Dimensions

The ANSI flange dimensions pdf are standardized in ANSI/ASME B16.5, which covers the dimensions of flanges and fittings used in piping systems. ANSI flanges come in a variety of sizes and are commonly manufactured in stainless steel, carbon steel, and alloy steel.

The ANSI flange pdf dimensions are also specified in different aspects such as:

Inches

The ANSI flange dimensions are specified in inches and can be classified as either small or large diameter flanges. Small diameter flanges have an inside diameter (ID) of less than 3 inches, while large diameter flanges have an ID of 3 inches or greater.

Surface Thickness

The ANSI flange dimensions are also specified by the thickness of the flange face (the flat surface that mates with the mating surface on the pipe or fitting). The standard thicknesses are 1/4 inch, 3/8 inch, 1/2 inch, and 3/4 inch.

Bolt Circle Diameter

The ANSI flange dimensions also include the bolt circle diameter (BCD), which is the diameter of the circle that the bolts pass through. The standard bolt circle diameters are 2 inches, 2-1/2 inches, 3 inches, 4 inches, 5 inches, and 6 inches.

Finally, the ANSI flange dimensions include the number of bolts per flange. The standard number of bolts is 8, but other numbers are available upon request.

If you’re looking for flanges ANSI in a specific size or thickness, or if you need help choosing the right flange for your application, please contact Oflange. They can help you find the right flange for your needs, and they can provide expert advice on how to use them safely and effectively in your piping system.

6. ANSI Flange Average Price

ANSI flanges are used in a variety of industries, making them a popular choice for many applications. However, because of their popularity, the flange ANSI average price can vary significantly depending on the size and type of flange you need.

Generally, ANSI flanges range in price from $50 to $500 each, but this can vary depending on the size and type of flange you need. For example, ANSI Class 150 flanges are less expensive than ANSI Class 300 flanges, and smaller flanges are also typically less expensive than larger ones.

The main factors that affect the cost of an ANSI flange are the size and type of flange, as well as the material it is made from. Other factors, such as the manufacturing process and shipping costs, can also affect the final price.

If you’re looking for ANSI flanges, be sure to compare prices to find the best deal. And keep in mind that the ANSI flange average price can vary depending on the size and type of flange you need.

a

7. 7 Ways to Properly Maintain ANSI Flange

ANSI flange is a must-have for any piping conformity assessment system. It is used to connect pipe segments and valves, and to allow the flow of fluids or gases between them.

ANSI flange is available in different sizes and some reducing flanges crafted in a cast or forged materials, so it’s important to choose the right one for your needs. To ensure that your ANSI flange types perform their best, it’s important to properly maintain it.

Here are seven ways to do just that:

#1 Inspect It Regularly

Inspect your ANSI flange standard regularly. Make sure to check for signs of wear and tear, corrosion, and damage. If you find any problems, repair or replace them as soon as possible.

#2 Keep It Clean

Keep your ANSI flange clean. Dirt, dust, and other debris can cause corrosion and damage. Wipe your ANSI flange down with a clean cloth regularly.

#3 Lubricate It Periodically

Lubricate your ANSI flange periodically. This will help keep it in good condition and prevent wear and tear.

#4 Make Sure You’re Using the Right Tools

Use the right tools when installing or removing your ANSI flange. Improper use can damage the flange and lead to leaks.

#5 Be Careful When Working With It

Be careful when working with the ANSI flange. It’s easy to damage or contaminate the surfaces if you’re not careful.

#6 Store It in a Safe Place

Store your ANSI flange in a safe place when it’s not in use. This will help prevent damage and keep it in good condition.

#7 Consult Manufacturer for Maintenance

Consult ANSI flange manufacturer for proper maintenance. Every ANSI flange is different, so it’s important to follow the specific instructions provided by the manufacturer.

By following these tips, you can ensure that your ANSI flange lasts for years to come.

8. 6 Tips on How to Choose the Right ANSI Flange for Your Needs

When it comes to choosing the right ANSI flange for your needs, it’s important to do your research and know what to look for. Here are some tips to help you make the right decision:

#1 Know the Specifications That You Need

The ANSI flange specifications that you need will vary depending on your project. However, there are some general guidelines to follow when choosing a flange. Here are some of the most important things to consider:

- The type of pipe connection (threaded, welded, slip-on, etc.).

- The size and pressure rating of the flange.

- The material of the flange.

- The type of gasket required.

Once you know what you need, you can start comparing different ANSI flanges to find the right one for your project.

#2 Choose a Supplier That Has a Wide Range of Options

When choosing a supplier for ANSI flanges, it’s important to find one that has a wide range of options. This will ensure that you can find the right flange for your needs, no matter what your project requires. In addition, it’s important to find a supplier that has a reputation for quality products and excellent customer service.

#3 Compare Prices and Quality

Compare prices and quality before making a purchase. It’s important to compare prices and quality before making a purchase. This will help ensure that you get the best value for your money.

#4 Ask the Supplier Questions

Ask the supplier questions about the ANSI flanges they offer, and other important questions related to the machine you are trying to purchase before making a decision.

#5 Check the Warranty and Return Policy

It’s important to check the manufacturer’s warranty and return policy before making a purchase. This will help protect you if something goes wrong with the product.

In addition, it’s a good idea to ask the supplier questions about the ANSI flanges they offer, and other important questions related to the machine you are trying to purchase before making a decision.

#6 Inspect Before Purchasing

It’s important to inspect the ANSI flanges before installation. This will help ensure that they are of the highest quality and meet your specific needs.

By following these tips, you can be sure to choose the right ANSI flange for your needs and avoid any potential headaches down the road.

To learn more about the ANSI flange, watch this video.

9. Conclusion

Avoid equipment failure and keep your business running smoothly with the help of the ANSI Flange. The ANSI Flange is a critical component in many industrial and commercial applications.

It helps to avoid equipment failure and keep your business running smoothly. By ensuring that your equipment has the best possible chance of avoiding failure, you can rest assured that your business will continue to run as efficiently as possible.

This will save you time, money, and headaches in the long run. Contact us at Oflange today to learn more about how the ANSI Flange can benefit your business!