PRODUCT FEATURES

4 Slip on Flange Manufacturer to Rocket Your Business

PRODUCTS

Proud To Offer A Wide Variety Of Flanges

If you are looking for something specific that isn’t listed on our website yet, just contact us today!

ABOUT US

Who Is Oflange.com

oflange.com have seen that today there are also many flange companies in China & internationally. However, their solutions were still stuck a few years ago.

In fact, we have been upgraded in recent years, and oflange.com hope our smart and flexible solutions can inject fresh blood into this market.

PARTNER

Who Trust Us

BUYER’S GUIDE

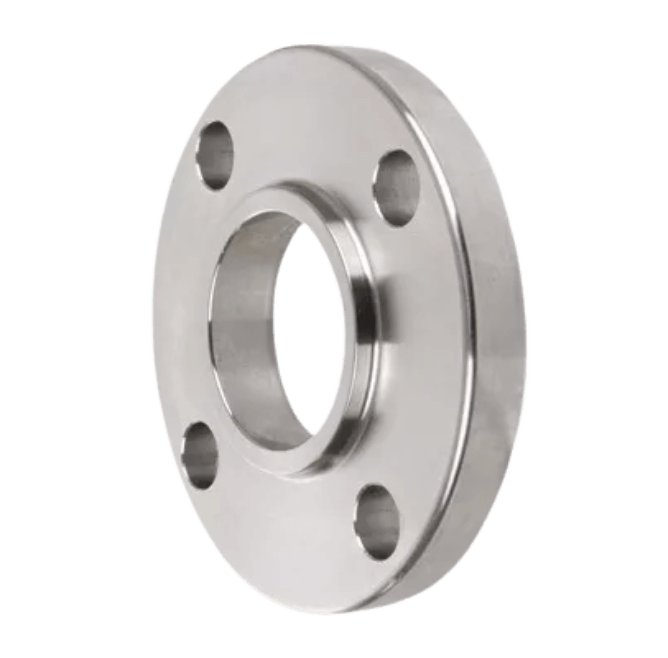

4″ Slip on Flange

There is no doubt that flanges are an essential part of any piping system. But when it comes to slips on flanges, there can be some confusion about what they are and how they are used.

Slip on flanges are an essential part of many piping and tubing systems, and they come in a variety of different types and sizes. If you are not familiar with slip on flanges, this blog post is for you!

We will discuss the four main types of slip on flanges and how they differ from each other. We will also talk about some of the benefits of using slip on flanges in your business. Let’s get started!

Table of contents

1. 4″ Slip on Flange Definition

A 4″ slip on flange is a type of flange that slides over the pipe and has a little larger interior design than the pipe.

The SO flange can be immediately connected to equipment or pipe by fillet welding at the top and bottom of the flange since the inner diameter of the flange is slightly larger than the outer diameter of the pipe. It’s utilized to get the pipe into the flange’s inner hole.

They are made of either steel or cast iron, and contain holes for bolting the piping to the surface of the 4″ slip on flange. These types of flanges are commonly used in plumbing applications because 4″ is a standard size for pipework.

A 4″ slip on is commonly used in the following industries:

- Plumbing industry

- Water system and sewage applications

- Oil and gas industry

- Power generation

- Shipbuilding

2. Different Class of 4″ Slip on Flange

Here are the different class of 4″ slip on flange.

| Class 150 | It is designed for use in low-pressure applications, such as fuel and water lines, up to a maximum of 400 psi. |

| Class 300 | Designed for use in higher-pressure applications up to a maximum of 1,000 psi. |

| Class 600 | Designed for use in even higher-pressure applications up to a maximum of 3,000 psi. |

| Class 900 | Designed for use in the highest-pressure applications up to a maximum of 6,000 psi. |

| Class 1500 | Designed for use in the highest-pressure applications up to a maximum of 15,000 psi. |

| Class 2500 | Designed for use in the highest-pressure applications up to a maximum of 25,000 psi. |

Class 150

A Class 150 4″ slip on flange is made to American National Standards Institute (ANSI) B16.5 specifications. It is designed for use in low-pressure applications, such as fuel and water lines, up to a maximum of 400 psi.

Class 300

A Class 300 4″ slip on flange is also made to ANSI B16.5 specifications, but is designed for use in higher-pressure applications up to a maximum of 1,000 psi.

Class 600

A Class 600 4″ slip on flange is made to ANSI B16.5 specifications and is designed for use in even higher-pressure applications up to a maximum of 3,000 psi.

Class 900

A Class 900 4″ slip on flange is made to ANSI B16.5 specifications and is designed for use in the highest-pressure applications up to a maximum of 6,000 psi.

Class 1500

A Class 1500 4″ slip on flange is made to ANSI B16.5 specifications and is designed for use in the highest-pressure applications up to a maximum of 15,000 psi.

Class 2500

A Class 2500 4″ slip on flange is made to ANSI B16.5 specifications and is designed for use in the highest-pressure applications up to a maximum of 25,000 psi.

Choosing the right class of 4″ slip on flange for your application is essential for ensuring safe and reliable operation. Make sure you select the right one for your specific needs.

3. The Difference Between 4″ Slip on Flange and Other Flange Types

Here are some of the differences of a 4″ slip on flange with other flange types.

- The internal pressure strength of a slip on flange is two-thirds that of a weld neck flange.

- The steel slip on flange has a durability life of 1/3 that of the other flanges.

- For slip on flanges, two fillet welding procedures are necessary, one on the inside and one on the outside.

- During welding, a space between the end of the pipe and the end of the flange must be left to avoid damaging the flange face.

- A slip on flange must first attach to a pipe, then to a fitting. (Flange+elbow or flange+tee combinations are not available since the fittings are not in a straight end and hence cannot glide completely into the flange bore.)

Because slip-on flanges are typically less expensive than other types of flanges such as raised face flange, many clients prefer them. It is one of the most used flanges for low-pressure, medium-temperature piping.

However, because the flange bore is greater than the pipe diameter, it typically necessitates more welding than other flanges. As a result, the flange’s durability is not as good as the welding neck flange’s. All of these considerations should be taken into account before selecting the proper flange.

4. 4″ Slip on Flange Material Types

Here is the variety of materials that are available for 4″ slip on flanges:

Carbon Steel

Carbon steel is the most common type of metal used in 4″ slip on flanges. It is strong and affordable, but it can rust if it is not properly maintained.

Stainless Steel

Stainless steel is a more expensive option, but it is corrosion-resistant and will not rust over time.

Aluminum Steel

Aluminum is a lightweight metal that is ideal for projects where weight is a concern. However, it is not as strong as carbon steel or stainless steel.

Brass

Brass is a durable metal that does not corrode like carbon steel or aluminum. It is also more expensive than other materials.

Each material has its benefits and drawbacks, so it is important to choose the right one for your project. Which material you choose will depend on your specific needs and budget.

5. Pipe Sizes Under Class 150 Slip on Flange

Slip on flange dimensions are covered in American Society of Mechanical Engineers (ASME) B16.5. Here are the nominal pipe sizes under Class 150 Slip on flange.

- 2″

- 3″

- 4″

- 6″

- 8″

- 10″

6. Slip on Flange Dimensional Inspection

Then you should look for the following things during a dimensional inspection of a slip on flange:

Body Diameters (Outer & Inner)

The body diameter is the size of the flange at its widest point. This is measured from one outer edge of the flange to the opposite outer edge. The inner diameter is the size of the hole in the middle of the flange.

Bolt Hole Diameter & Bolt Circle

The bolt hole diameter is how wide the hole is for bolting the flange to another flange or fitting. This is measured from one side of the hole to the other side, perpendicular to the bolt circle.

The bolt circle is the diameter of the circle that would be drawn if you connected all of the number of bolt holes with a line.

The Hub’s Length

The hub length is how long the part of the flange that sticks out from the bolts is. This dimension is important if you’re trying to make sure the flange will fit over a pipe or fitting.

The Bolt Hole’s Straightness and Alignment

The bolt hole’s straightness and alignment are important for ensuring that the bolts will be able to go in straight and without any wobble. If they’re not aligned properly, it could lead to a lot of wear on the bolt hole and the bolt itself.

These are the most important slip on flange dimensions 150 to look for when inspecting a 4″ slip on flange. Make sure to compare them with the dimensions of the flange you’re using to ensure they are compatible.

7. 4″ Slip on Flange Manufacturing Process

Here is a step by step guide on how 4″ slip on flange is made.

Step #1 Cutting of Raw Materials

The flange is manufactured using several different materials. It can be made of steel flange, cast iron or ductile iron. The flange needs to be flame cut according to the manufacturer’s specifications before it is machined and welded together with other parts of flange assembly.

Step #2 Heating in High Temperature

The flange needs to be heated at high temperature. The flange must be consistent and uniform surface finished during this process as it will help keep flange from leaking under pressure.

Step #3 Forging

The flange is forged in a press. This will help to achieve the desired shape and size for the flange.

Step #4 Machining

The flange is then machined using CNC machines. The holes are drilled and the flange is precision-machined to ensure that it has right shape and size for flange to perform its function effectively.

Step #5 Welding

The flange is welded together with other parts of flange assembly using the TIG welding process. This will help to achieve the desired strength and durability for the flange.

Step #6 Testing

The flange is then tested for leaks and other defects before it is sent to the customer. It is important to test the flange under pressure to ensure that it meets the requirements.

Step #7 Packaging and Delivery of the Flange

The flange is then packaged and delivered to the customer. It is important to note that flanges are heavy and bulky, so they will require a lot of space during transportation.

8. The Benefits of Using 4″ Slip on Flange

Here are some of the benefits of using a slip on flange.

Increased Efficiency

Installing a slip on flange can lead to increased efficiency when connecting or disconnecting piping systems. This is because the 4″ slip on flange provides a more secure connection than traditional methods.

Reduced Leaks and Spills

One of the primary benefits of using a 4″ slip on flange is that it helps to reduce leaks and spills. By providing a tight seal, it helps to keep contaminants and other materials from escaping, helping to keep your workplace or environment safer.

Increased Durability

When two pipes are joined together, there is always some degree of movement and vibration. A slip on flange helps to absorb this movement and prevent damage to the pipe joints. This can help to extend the life of your piping system and reduce the need for repairs or replacements.

Ease of Installation

Installing a 4″ slip on flange is a breeze, thanks to its simple design. All you need is a wrench to tighten the bolts, making it a quick and easy process. This can save you time and money, as there is no need for special tools or expertise.

Versatility

A 4″ slip on flange is versatile and can be used in a wide range of applications. It is perfect for connecting pipes of different sizes and materials, making it a handy tool to have on hand. Whether you are installing a new plumbing system or repairing an existing one, a slip on flange is a valuable asset.

Lower Installation Cost

One of the biggest benefits of using 4″ slip on flanges is that they can help reduce installation costs. This is because they are much easier to install than traditional flanges, which require welding or bolting in place.

With slip on flanges, all you have to do is slide them over the ends of your pipes and tighten the bolts. This can save you a lot of time and money when installing a new piping system.

Easier Alignment

One of the benefits of using a 4″ slip on flange is that it is easier to align than other types of flanges. This is because the slip on flange has a tapered seat that makes it easy to line up with the pipe. This can save you time and money when you are installing the flange.

If you are looking for a 4″ slip on flange, we highly recommend checking out our selection here at Oflange. We offer some of the best prices on the market, and our products are of the highest quality.

9. 4″ Slip on Flange Average Cost

The price of a 4″ slip on flange can vary depending on the brand, the type of metal, quantity and the size (in inches). In general, the cost is between USD 25 and USD 50.

If you need to find a 4″ slip on flange, it is best to shop around online or at your local hardware store. You will likely find the details, availability of products and best prices at online page or online retailers such as Oflange.

Just be sure to take the pipe size, type of metal, and brand into account when you are shopping. This will help ensure that you get the best price for your needs.

10. 7 Maintenance Tips for 4″ Slip on Flange

Here are tips on how to maintain a 4″ slip on flange.

#1 Inspect the Flange Regularly for Any Damage or Wear

If you notice any damage or wear, it is best to replace the flange as soon as possible. This will help prevent further damage and ensure that the flange continues to function properly.

#2 Keep the Bolts Tight

Make sure to keep the bolts on the 4″ slip on flange tight at all times. This will help keep the flange in place and ensure a tight seal.

#3 Lubricate the Gasket

The gasket on the 4″ slip on flange can wear down over time. You can help prolong its life by lubricating it with a silicone-based lubricant.

#4 Make Sure Flange is Free From Any Debris

Make sure to regularly clean the 4″ slip on flange and remove any debris or buildup. This will help ensure a tight seal and reduce the risk of leaks.

#5 Avoid Dropping or Banging the Flange Against Hard Surfaces

If you drop or bang the 4″ slip on flange against a hard surface, it can cause damage to the flange and gasket. This can lead to leaks and other problems down the road.

#6 Immediately Replace Damaged Flange

If the 4″ slip on flange is damaged in any way, it is best to replace it immediately. This will help prevent further damage and keep your plumbing system running smoothly.

#7 Follow the Manufacturer’s Instructions

After reading the options description of the product be sure to follow the manufacturer’s instructions for cleaning and maintenance. This will help ensure that your 4″ slip on flange stays in good condition.

11. Conclusion

A 4″ slip on flange is a versatile and handy tool to have around. It can be used in a wide range of applications, and it can help reduce installation costs.

Be sure to take the size, type of metal, and brand into account when shopping for a 4″ slip on flange. And remember to keep the flange maintained regularly for a longer lifespan.

If you have any other questions about 4″ slip on flanges, please do not hesitate to contact us at Oflange. We will be glad to assist you!