PRODUCT FEATURES

Threaded Flange Manufacturer to Rocket Your Business

PRODUCTS

Proud To Offer A Wide Variety Of Flanges

If you are looking for something specific that isn’t listed on our website yet, just contact us today!

ABOUT US

Who Is Oflange.com

oflange.com have seen that today there are also many flange companies in China & internationally. However, their solutions were still stuck a few years ago.

In fact, we have been upgraded in recent years, and oflange.com hope our smart and flexible solutions can inject fresh blood into this market.

PARTNER

Who Trust Us

BUYER’S GUIDE

Threaded Flange: What You Need to Know

As a business owner, you know the importance of staying ahead of the competition. You also know that sometimes you have to make tweaks to your processes in order to do so. If you’re looking for a way to make your process more efficient, consider using threaded flanges.

Threaded flanges are a great way to join two pieces of metal together, and they’re very easy to use. In fact, you can probably use them without any help from an engineer or technician. Plus, they’re much more durable than traditional welds, which means they’ll last longer even under heavy stress.

In this article, we’ll take a closer look at threaded flanges and how they can benefit your business. If you’re interested in learning more about threaded flange standards, keep reading! We’ll explain what they are and how to use them.

Table of contents

1. Threaded Flange Definition and Its Uses

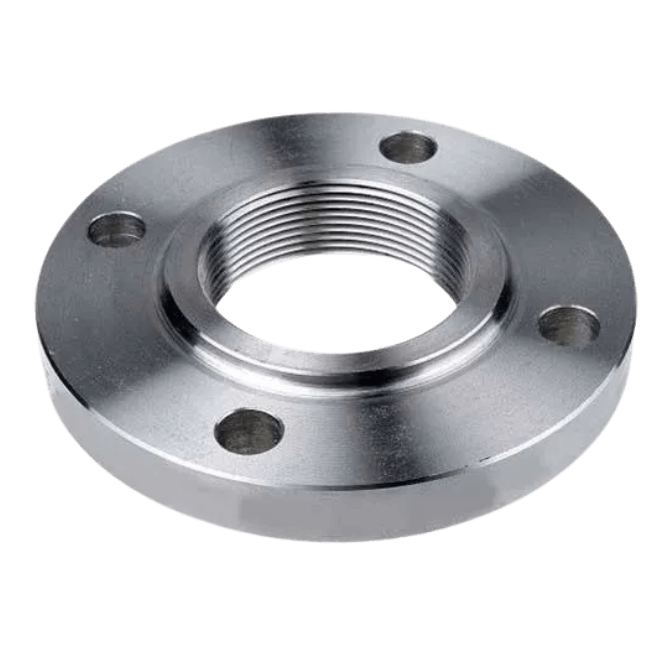

Threaded flanges are a type of flange that has a threaded hole in the center. This hole allows you to attach a bolt, which then holds the flange in place. Threaded flanges are usually used to join two pieces of metal together.

Threaded floor flange is very easy to use. In fact, you can probably use them without any help from an engineer or technician. Plus, they’re much more durable than traditional welds, which means they’ll last longer even under heavy stress.

Threaded flanges are often used in conjunction with threaded fittings. They provide a means of connecting two threaded pipe flanges, while also providing a seal that prevents leakage.

Additionally, threaded flanges can also be used to create a union between two threaded flange pipes, which allows for the easy removal of one of the pipes without having to disconnect the entire assembly.

Threaded flanges are great because they can be used for so many different purposes. Some threaded flange uses include:

- joining two pieces of metal together

- creating unions between threaded pipes

- creating threaded flange joints that can be taken apart later without damaging the threaded flange itself.

The threaded flanges fabrication has been the most important need of today’s industries and it will remain so in future as well.

2. Parts & Construction of Threaded Flange

Several parts make up a threaded flange: the flange itself, the bolt, and the nut.

Flange

The flange is the part that attaches to the pipe flange or other piece of metal. The flange is usually made out of cast iron, steel threaded flange class, or stainless steel threaded flange. The flange has threaded holes and raised surfaces that correspond to where the nut and bolt will go.

Bolt

The threaded flanges have a round metal edge with threaded bolt holes in the center. They’re designed to be attached to the end of a pipe or another material that needs to be connected to another part or section. The threaded hole allows you to screw in a bolt, which holds the threaded flange in place.

Nut Screw

The nut is externally threaded plate flanges as well, with a hexagonal portion at the bottom for tightening it onto the bolts. One side of this hexagon has been flattened off so you can easily tighten it onto your bolts without any issues.

The screwed flange part of the nut allows it to thread into your threaded flange. You also need a flat washer to prevent metal from seeping through the hole in the flat side of your nut screw. This keeps your threaded flange from leaking.

3. The Manufacturing Process of a Threaded Flange

The manufacturing process for threaded flanges is very simple. Threaded flanges are already finished when they’re sent out to customers, which means you can get to work right away.

Below are the steps that threaded flanges go through during the manufacturing process:

Step #1 Mix the Materials

The materials used to make threaded hub flange are very simple. In fact, most threaded flanges only have three ingredients: cast iron, steel, and zinc. Sometimes you’ll see threaded flanges made out of copper or aluminum as well.

Step #2 Mold and Cool the Mixture

Once all of your material is mixed together, they’re set into a mold. This gives them their shape while they cool down.

Step #3 Clean the Flange

The final step in this process is to clean off your threaded flange so it’s ready for use. Machinery applies an electrochemical bath that cleans your flange without damaging the material.

To know more about how flanges are manufactured, check out this video!

4. Advantages and Disadvantages of Threaded Flange

As you can see, threaded flanges are very easy to use. Threaded flanges also have several advantages over welds and other types of flanges.

Threaded Flange Advantages

Some of the advantages include the following:

- Threaded flanges are much more durable than welds

- Threaded flanges require less time

- Threaded flanges are easier to install

- Threaded flanges are cheaper

- Threaded flanges come in a wider variety

- Threaded flanges can be used to join many types of metals

- Threaded flange join two pieces of metal together

Threaded Flange Disadvantages

- They’re not as strong as some other types of flanges.

- Your threaded flange will likely leak if you don’t use the correct gasket.

| ADVANTAGES | DISADVANTAGES |

|---|---|

| Much more durable than welds | They’re not as strong as some other types of flanges |

| Require less time | Will likely leak if you don’t use the correct gasket |

| Cheaper | |

| Come in a wider variety | |

| Can be used to join many types of metals | |

| Join two pieces of metal together |

5. Applications of Threaded Flange in Various Industries

In addition to joining two pieces of metal together, it can be very useful for other purposes. Threaded flanges are not just limited to the plumbing industry. Threaded flanges have many applications in various industries.

In fact, threaded flanges have been used in a variety of ways for over a century! Some of the other uses for threaded flanges include:

Gas Supply Industry

Gas supply threaded flanges are commonly used in the gas supply industry. Threaded flanges allow you to attach a pressure regulator to your pipe quickly and easily. Threaded flanges are also used to attach a gas meter to the piping system. Threaded flanges save time and energy, as opposed to welds or clamps.

Water Supply Industry

Water supply threaded flanges are also used in the water supply industry. Threaded flanges are used to attach valves, pressure gauges, and stop cocks. Threaded flanges allow you to install these parts easily without wasting any time or money.

Food Service Industry

Food Service Industry threaded flanges are also commonly used in the foodservice industry. Threaded flanges attached to meat grinders help give the tool its power by bringing it back down to a low speed.

Threaded insert with flange also connects tables to the floor, which allows waiters and customers easier access. Threaded flanges are also used in kitchens to attach air hoses to various equipment, such as food mixers and bread machines.

Oil & Gas Production Industry

Threaded flanges are used in the oil and gas production industry to connect tubing. Threads on the underside of the flange make it easy to attach two pieces of tubing together without welding or clamps. Threaded flange connection also increases your flow rate, which can save you money in the long run.

Shipbuilding Industry

Shipbuilding Threaded ship flanges are also quite popular. This application is especially useful when attaching heavy machinery to the ship’s surface. Threaded flanges are used to easily attach heavy machinery.

Threaded flange shipbuilding industry is great for the installation of turbines, cranes, and other large machinery that would be difficult to install without threaded flanges.

Trailer Manufacturing Industry

Trailer Threaded Flanges are also used in the manufacturing of trailers. Threaded flanges allow you to easily install a trailer ball to your trailer, which can be very useful if you need to haul large objects.

Auto & Truck Manufacturing Industry

There’s also a wide range of threaded auto & truck parts benefits over welds. Threaded car & truck threaded fittings offer faster installation times than welds.

So then, there you have it. Threaded flange joints can be very useful for a variety of purposes. They’re not just limited to the plumbing industry! Threading flanges have been used in industries worldwide for over a century. This is one of the reasons why so many people use them on a daily basis.

6. Threaded Flange Average Cost

The threaded flange average cost can vary depending on the flange threaded type and size of threaded flange you need. Approximately, threaded flanges can range anywhere from $10 to $20 per threaded flange. There are different threaded flange types that you may need, which can affect the threaded flange average cost.

There are many threaded Flange manufacturers out there, so it is important to do your research before choosing one. You should also be sure to know the threaded flange average cost before you buy.

For more information about threaded flanges, contact us at Oflange today!

7. Where to Purchase Threaded Flange in Bulk

If you’re looking to purchase threaded flanges in bulk, there are a few different places you can go.

Distributor

One option is to purchase threaded flanges from a distributor. A distributor will have a wide variety of threaded flanges available, and they will be able to help you find the right threaded flange for your needs.

Manufacturer

Another option is to purchase threaded flanges from a manufacturer. This option can be a little more expensive, but you’ll be able to get exactly the type of threaded flange you need.

Oflange is one of the threaded flange manufacturers out there. To find threaded flanges, contact us today!

Online

Finally, you can also purchase threaded flanges on eBay or other online marketplaces. This can be a more affordable option, but you’ll need to be sure that the threaded flange is the exact threaded flange you need.

8. 5 Tips to Select the Right Threaded Flange for Your Needs

Now that you know threaded flanges are used in a variety of different applications, there are some tips to select the right threaded flange for your needs.

#1 Threaded Flange Type

First, it’s important to consider what threaded type you need. There are two main types: threaded and grooved threaded flanges. Threaded flanges are threaded on the inside, which allow you to use threaded rods for strength.

Grooved threaded flanges have threaded holes around the outside, which allows you to screw threaded plugs into threaded flanges instead of threaded rod flange.

#2 Threaded Flange Size

Second, you should consider your threaded flange size. It’s important that you know what threaded flange size you need before you buy threaded flanges.

#3 Threaded Flange Style

And finally, threaded flange style should also be taken into consideration. Threaded flange styles include threaded flanges with a raised face, threaded flanges without a raised face, and threaded flange styles with the nose hole as the same as the other threaded holes.

#4 Threaded Flange Manufacturing

There are many threaded flange manufacturing processes out there. Some threaded flange manufacturing processes include cold forging, hot forging, and casting. Manufacturing process can influence threaded flange prices.

#5 Threaded Flange Material

Threaded flanges can be made out of a variety of different materials. Some threaded flange materials include cast iron, steel, brass, and aluminum.

To find high quality threaded fittings at an affordable price, contact Oflange today!

9. Conclusion

We hope that this article has helped you find threaded flanges that are cost-effective and meet your needs. Threaded flange fittings are versatile, but it’s important to choose threaded flanges that match what threaded flanges you need.

These threaded flanges are also affordable, so if you’re looking for threaded flange fittings at an affordable price, contact us at Oflange today.