PRODUCT FEATURES

Plate Flange Manufacturer to Rocket Your Business

PRODUCTS

Proud To Offer A Wide Variety Of Flanges

If you are looking for something specific that isn’t listed on our website yet, just contact us today!

ABOUT US

Who Is Oflange.com

oflange.com have seen that today there are also many flange companies in China & internationally. However, their solutions were still stuck a few years ago.

In fact, we have been upgraded in recent years, and oflange.com hope our smart and flexible solutions can inject fresh blood into this market.

PARTNER

Who Trust Us

BUYER’S GUIDE

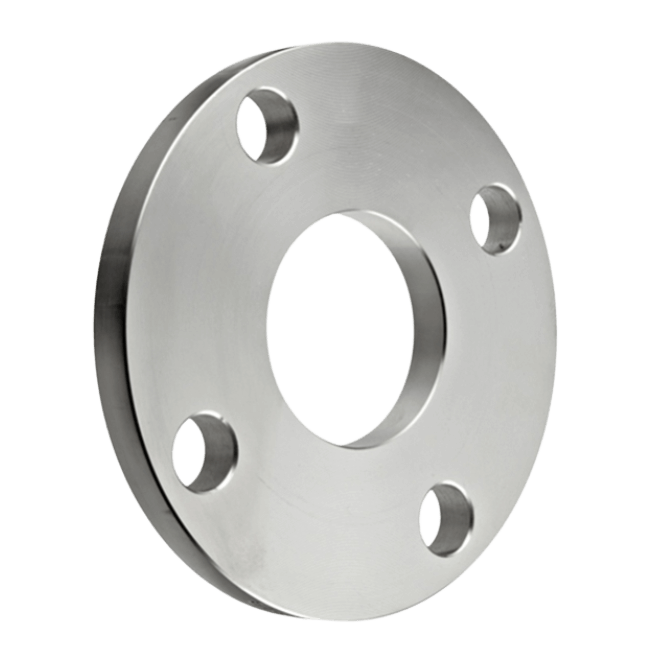

Plate Flange

Looking for an industrial-strength gasket? Look no further than Plate Flange! Plate flanges are used to connect piping and tubing systems or as a means of joining two pieces of sheet metal. It’s simple to use and extremely strong, making it a great choice for a variety of applications.

The flange is welded to one piece of metal and bolts are used to secure the second piece of metal to the flange. This creates a strong, durable connection that can handle heavy loads.

Table of contents

1. Plate Flange Definition and Its Uses

What is a plate flange? A Plate Flange is a type of flange that is used to connect two pieces of metal. It is made from heavy-duty materials and can withstand even the most extreme conditions. Plate Flanges are also simple to use – the welding process is simple and easy to learn, even for beginners.

This makes them the perfect system for creating custom welds and repairs on any duplex steel plate. Plate Flanges can be connected to a variety of different metals including steel, cast iron, and aluminum. Plate flanges are available in different sizes and shapes.

Plate flanges come in round or square flange plate with varying hole configurations according to the material they need to be connected to. Blind Flanges are perfect for creating custom-made metal pipes, beams, brackets, plates, and much more. Plate flanges are also perfect for when you need to correct or repair a problem in existing metal structures.

Plate gaskets allow the use of two pieces of metal to be joined together using bolts or screws that fit into the Plate Flange. Plate flange is a gasket-type element, offered in various types depending on the material used and the application required.

Plate flanges are commonly used on all sorts of industrial applications such as wind turbines, heavy-duty vehicles, and cranes to name just a few. Plate flange is often used in situations where strength and durability are essential.

2. The Different Types of Plate Flanges

Plate flanges are a type of flange that is used to connect pipes and tubes. Plate flanges come in different sizes and shapes, and there are a variety of different types of plate flanges available.

Some of the most common types of plate flanges include the following:

Slip On Plate Flange

The slip-on plate flange is the most common type of plate flange. This type of flange is easy to install and is typically used for low-pressure applications. The slip on flanges is a simple, circular flange that has a hole in the center for the pipe or tube to be attached.

This type of flange typically has a lip on the edge that helps to keep the seal in place.

Weld Neck Plate Flange

Weld neck plate flanges are a type of plate flange that is used to connect pipes and tubes. Weld neck plate flanges are available in a variety of sizes and shapes, and they are typically used for high-pressure applications.

Weld neck plate flanges have a protrusion on the neck of the flange that helps to create strong weld joint flanges. This type of flange is typically more expensive than other types of plate flanges, but it provides a stronger connection.

Socket Weld Plate Flange

The socket weld plate flange is a type of plate flange that uses a groove on the pipe or tube to create a seal. Socket weld plate flanges are typically used on low-pressure applications, and they are usually mounted by welding them to the pipe. This type of Plate Flange is sometimes called an ASA Plate Flange, or a Plate Flange.

Threaded Plate Flange

The threaded Plate Flange is a type of Plate Flange that includes threads on the side. The Plate Flange has two holes in it, and one Plate Flange hole lines up with the other Plate Flange hole to connect the Pipe or Tube.

This type of Plate Flange is commonly used for low-pressure applications that are designed to maintain a watertight seal.

Each type of plate flange has its unique benefits and drawbacks, so it’s important to choose the right type of plate flange for your needs.

3. Selecting the Right Plate Flange for Your Needs

When selecting the right plate flange for your needs, it’s important to consider the following factors:

Plate Material

A Plate flange can be made of any number of materials including carbon steel, stainless steel, aluminum, and many others. The material choice depends on your application, process conditions, and most importantly your budget.

To select the right plate flange for your needs, you’ll need to consider what is important most to you in terms of cost, strength, corrosion resistance, and ultimately the end use of your application.

Plate Flange Size

The Plate flange size is also an important consideration when selecting the right plate flange for your needs. Plate flanges are available in a variety of sizes, ranging from very small to extremely large.

Plate flange dimensions are typically denoted as the nominal size, which may not be the same as the Plate Flange outer diameter. When selecting a plate flange, it’s important to make sure that the size of the flange matches the size of the pipe or fitting to which it will be attached. Failing to do so can result in leaks and other problems.

Plate Flange Type

Another important consideration when selecting the right plate flange for your needs is the type of Plate flange. Plate flanges are available in a variety of types, including welding neck, slip-on, and threaded.

Each type of Plate flange has its advantages and disadvantages, so it’s important to select the type that best suits your needs.

When selecting the right plate flange for your needs, be sure to consider all of the factors discussed in this article. Doing so will help you select Plate flanges that are right for your needs and fit within your budget.

If you want detailed information on how to select the right flange for your application, check out this video.

4. Step by Step Guide to Install a Plate Flange

Installing a Plate Flange can be a daunting task. There are a few key steps that you need to take to make sure that the job goes as smoothly as possible.

Here is a step by step guide on how to install a Plate Flange:

| 1 | Make Sure Plate Flange is Clean |

| 2 | Plate Flange Positioning |

| 3 | Tighten Plate Flange Bolts |

| 4 | Plate Gasket Sealing |

| 5 | Plate Flange Bolting Check |

| 6 | Plate Flange Final Check |

Step#1 Make Sure Plate Flange is Clean

You need to make sure that Plate Flange is clean. You can use a rust remover product or some sandpaper to get rid of any loose material from the Plate Flange’s surface.

Step#2 Plate Flange Positioning

Position the Plate Flange so that it is almost in place. It should be within a few inches of the Plate Gasket, but not touching. The Plate Flange facing up should allow you to see the Plate Gasket protruding from its center; also make sure to align Plate Flange bolts with the Plate Gasket bolt holes.

Step#3 Tighten Plate Flange Bolts

Tighten Plate Flange bolts in sequence to make sure they are tight enough. Apply some soap solution on Plate Gasket; this will help you to avoid over-tightening Plate Flange bolts. Do not overtighten Plate Flange bolts as they may distort Plate Gasket and Plate Flange.

Step#4 Plate Gasket Sealing

Apply Plate Flange sealing compound to Plate Gasket, this will help you to avoid Plate Flange leaks. If Plate Gasket does not have any bolt holes then apply some sealant on the Plate Gasket surface where Plate Flange bolts are passing through it.

Step#5 Plate Flange Bolting Check

Check Plate Flange bolt tightening pattern by drawing a circle with Plate Flange bolts. After this, make sure all Plate Gasket bolt holes are covered by Plate Gasket and Plate Flange. Once it is confirmed, completely tighten Plate Flange bolts.

Step#6 Plate Flange Final Check

Performed a final check on Plate Flange installation, confirming that all bolts were tightened and no leaks were present. After that Plate Flange has been correctly installed.

Plate Flange installation is not that difficult but requires some of your time and attention. Plate Flange installation is a lot easier if you follow this Plate Flange Installation Guide.

5. Plate Flange Average Cost

Plate flanges are an important component of many industrial piping systems. They are typically used to join two or more pipes, and can also be used to mount equipment. Plate flanges are available in a variety of sizes and materials, and the cost can vary depending on the size and material.

The average cost for a plate flange is around $50.00, but the cost can vary depending on the size and material. Plate flanges are available in a variety of sizes, from 1/2 inch to 12 inches, and in a variety of materials, including steel, stainless steel, and aluminum.

Plate flanges are also available in different ratings, with different pressure rating classes. Plate flange cost generally increases when the size or material increases. Plate flanges are usually priced individually, so the cost of purchasing several plate flanges for a project can be significant.

6. Plate Flange Manufacturer

There are many Plate Flange Manufacturers throughout the world. Some of the more popular ones include:

Husteel Industry Group

Husteel Industry Group is a Plate Flange Manufacturer that has been in business since 1997. They are located in Qingdao, Nantong. Husteel is a quality-oriented company that focuses on the research and development of new products. They have a wide range of Plate Flanges that are made from carbon steel, stainless steel plate flanges, and alloy steel.

Red Earth Steels PVT LTD

Red Earth Steels PVT LTD is a Plate Flange Manufacturer that is headquartered in Mumbai, India. They have been in business since 2006. Red Earth Steels has Plate Flanges that are capable of withstanding pressure from both steam and oil. They have stainless steel plate flange that is heavy-duty, lightweight, and available in many different sizes.

Oflange

Oflange is a Plate Flange Manufacturer that is based in China. They have Plate Flanges that are made to be extremely durable and able to handle high heat. Oflange are used by many companies throughout the world.

These Plate Flange Manufacturers are just a few of the companies that can produce Plate Flanges. Contact any one of these companies directly for more information on their products and services.

7. 4 Tips for Maintaining Your Plate Flange

Plate flanges are an important part of many piping and tubing systems. They are used to connect pipes and tubes of different sizes and can also be used as a mounting point for other equipment. Plate flanges are typically made from steel, and they must be kept in good condition to ensure the safety of the system.

Here are a few tips for maintaining your plate flange:

#1 Keep Plate Flanges Clean

The plate flange is an area where dirt and debris can collect. To avoid this, make sure to clean the plate flange regularly using steam or water pressure.

#2 Inspect Plate Flanges for Damage

Damage to the plate flange is only likely to occur with heavy use over time. If the plate flange is bent or warped, it must be replaced to ensure safety. Plate flanges are usually only replaced if they aren’t in good condition; otherwise, they can be repaired by welding material over the damaged area to restore the plate flange to its original shape.

#3 Replace Plate Flanges if Necessary

Plate flanges are important parts of piping and tubing systems. They connect pipes and tubes of different sizes and can also serve as a mounting point for other equipment. Plate Flanges are typically made from steel, which must be kept in good condition to ensure the safety of the system. Plate Flanges should be inspected regularly for damage, such as warping or bending, and replaced if necessary.

#4 Lubricate Plate Flanges

The bolts on a Plate Flange may require lubrication to allow them to turn easily. To lubricate the bolts, you should apply a thin coating of grease or oil directly to the bolts and screws before installing them. Plate flanges may also need to be greased before removal if they have not been removed for a long time.

Overall, the steel plate flange is made up of steel and must be kept in good condition to ensure the safety of a system.

8. Common Problems With Plate Flanges and How to Solve Them

Plate flanges are a type of flange that is used to join two pieces of metal together. While they are generally reliable, there can be some common problems that can occur. Here are some of the problems and how to solve them:

Leaking Flange

A leaking flange can be caused by several factors, such as a bad seal, corrosion, or a crack in the flange. To fix this problem, take your hand and rub it over the circumference of the ring type joint gasket around the plate flanges. If you feel a gap, this may be where the leak is coming from. You can also consult with an expert to determine if the flange needs to be replaced or repaired for you.

Misaligned Flanges

When the flanges are not aligned properly, it can cause leaks, rusting on either side of the plate flange, and other problems. Plate flanges are very easy to align correctly because they have alignment marks that you can use as a guide.

Simply line up the marks for any misalignment that may exist on both sides of each flange. Then tighten the bolts to secure them in place.

Warped Flanges

Warped flanges can also lead to leakage and should be fixed as soon as possible. You can try to fix warped flanges by heating them until they are red hot, then letting them cool slowly. You can also try using a hydraulic press to flatten the flanges back out if they aren’t too warped.

Rusting Flanges

Plate flanges can rust if they are not properly coated or if they are exposed to moisture. To prevent rusting, make sure the flange is coated with a protective layer and keep it dry when not in use.

Therefore, if you are having problems with your plate flanges, there are some common troubleshooting steps that you can take to remedy the issue. In some cases, you may have to replace the flange to get it working again.

Plate flanges are a simple and effective solution for joining pipes together, but they can also be problematic when not maintained or handled properly.

9. Conclusion

Plate flanges are the best choice for your industrial application. They’re made from high-quality materials and they’re extremely durable, making them perfect for heavy loads. You can trust that our products will hold up to whatever you throw at them!

If you want to be sure that your equipment is safe and secure, then plate flanges are the way to go. We have all kinds of sizes available so you can find exactly what you need without any hassle or worry about whether it will fit properly or not.

Order your plate flange today on our website!