PRODUCT FEATURES

Orifice Flange Manufacturer to Rocket Your Business

PRODUCTS

Proud To Offer A Wide Variety Of Flanges

If you are looking for something specific that isn’t listed on our website yet, just contact us today!

ABOUT US

Who Is Oflange.com

oflange.com have seen that today there are also many flange companies in China & internationally. However, their solutions were still stuck a few years ago.

In fact, we have been upgraded in recent years, and oflange.com hope our smart and flexible solutions can inject fresh blood into this market.

PARTNER

Who Trust Us

BUYER’S GUIDE

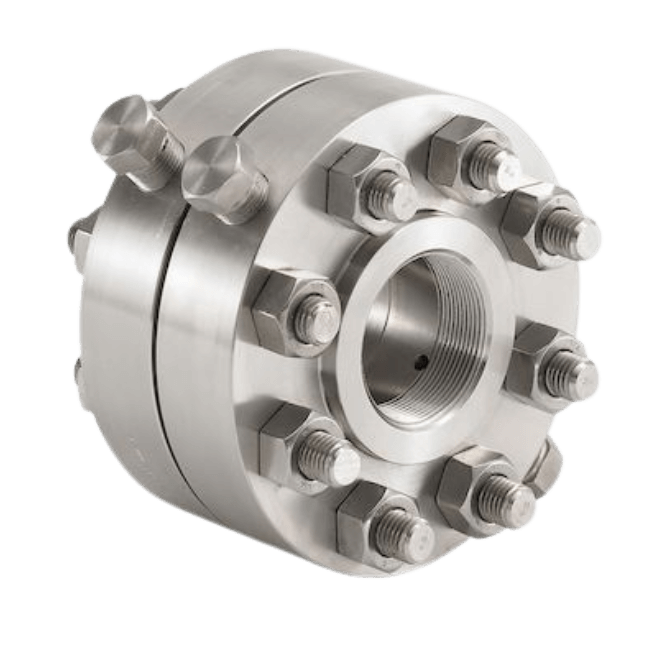

Orifice Flange

Orifice Flange is the perfect tool for sealing orifice fittings on pipelines. It can be used with a variety of materials, including metals, plastics, and composites. The flange is made of steel and has a zinc-plated finish for corrosion resistance. It also includes a gasket for a tight seal.

Orifice Flange is the perfect solution for connecting pipelines and other components in a fluid system. It provides a leak-free seal and easy installation, making it an essential part of any plumbing or piping system.

Table of contents

1. Orifice Flange Definition and What Does It Do

An orifice flange is a disc or ring-shaped device that is inserted into orifice plates to measure orifice flow rate. It has a hole in the center that allows fluid to flow through, and it is typically mounted on a pipe or tube. Orifice flanges are used in a variety of industries, including oil and gas, water treatment, and HVAC.

An orifice flange is a type of flange that is used to connect a pipe or tube to a valve or fitting. It is also used to measure or control the flow of fluid or gas through the pipe or tube. It is inserted into the pipe or tube and then welded or bolted in place.

The orifice plate flange has many different types and styles that are used for specific applications or to meet certain needs or uses. It can be made out of several different materials such as stainless steel, carbon steel, or brass.

The orifice flange is commonly used in fluid or gas delivery systems. It can be used to control the flow of liquid or gas into or out of a system or piece of equipment or it can be used to measure the amount or rate that liquid or gas is being fed into an output device, system, or component.

An orifice flange set is a type of orifice flange that is used to connect two pipes or tubes. It is typically used in piping systems that require a high degree of accuracy or precision. It has two or more flanges that are connected by an orifice flange jack screw or bolts. This allows for a more secure connection and helps to prevent leaks.

2. Types of Orifice Flanges and Their Uses

Generally, orifice flanges are used to control or measure the flow of gas or liquid into or out of a product or system. They can also be used to measure the amount or rate that gas or liquid is being fed into an output device, system, or component.

Different types of orifice flanges and their uses are described below:

Orifice Flange With Weld Neck

Orifice flange with weld neck is designed to connect to a pipe or tube that has a raised or beveled neck. It is welded to the pipe or tube, and the orifice plate is then bolted to the orifice flange. This type of orifice blind flange is often used in high-pressure drop or high-temperature applications.

Orifice Flange With Threaded Connection

Orifice flange with threaded connection is designed to connect to a pipe or tube that has a threaded or screw-on end. The orifice flange is screwed or bolted onto the pipe or tube, and the orifice plate is then screwed or bolted onto the orifice flange. This type of orifice flange is often used in low or medium-pressure or low or medium-temperature applications.

Slip on Orifice Flange

A slip-on orifice flange is designed to connect to a pipe or tube that has a slip on and threaded. The orifice flange is bolted to the pipe or tube, and the orifice plate is then bolted to the orifice flange. This type of orifice flange is often used in low-pressure or low-temperature applications.

3. Installation of Orifice Flanges

Installation of orifice flanges is an important process in many industries. Orifice flanges must be installed properly to ensure that the machinery continues to run smoothly. There are a few key steps in the installation process that should be followed to ensure a successful installation.

Here are the steps for orifice flange installation:

Step #1 Ensure Correct Orifice Flange Is Being Installed

This may seem obvious, but orifice flanges come in a wide variety of different types and sizes. Make sure you have purchased or been provided with the correct orifice flange for your machinery before starting the installation process.

Measure the orifice flange before you try to install it by holding the orifice flange against the orifice. Mark or note where it needs to be cut or trimmed.

Step #2 Ensure Hole in Orifice Is Clean

Use a wire brush to clean the area of any dirt, rust, or another contaminant that may have gathered around the threaded or orifice end of the orifice flange. A wire brush or a high-pressure water nozzle should be able to clear away any contaminants from around the orifice flange.

Step #3 Measure Orifice Flange

Use a ruler or tape measure to get an accurate measurement of where the orifice flange will need to be cut or trimmed. Use a marker or pen to mark or point out where the orifice flange needs to be cut or trimmed.

Step #4 Cut or Trim Orifice Flange

Make sure you have safety goggles/glasses on before starting this step to ensure that metal shavings don’t fall into your eyes. Use ahacksawor similar tool to cut or trim the orifice flange. Ensure that it is a clean, straight cut by using a file or sander to smooth over any rough or jagged edges or sides after cutting or trimming.

Step #5 Thread or Force Orifice Flange Into the Hole

Start threading or forcing the orifice flange in using your hands or by using awrenchor socket. Slowly turn or screw the orifice flange clockwise or in an upwards direction to ensure that it starts threading or forcing into place. Turn or screw the orifice flange into place until it is firmly secured and cannot be unscrewed anymore.

Step #6 Check for Leaks

If you are using orifice flanges for a water or gas application or similar fluid or material, check for leaks by filling the orifice flange with the liquid or material to be used. Turn on the machinery and ensure that there are no leaks or other problems.

Step #7 Applying Sealant

If you cannot find any leaks after checking, use some type of sealant or adhesive to ensure that the orifice flange is firmly secured and cannot be unscrewed or unsealed, or removed from the orifice.

Step #8 Check Orifice Flange Again

After applying and allowing some time for the sealant or adhesive of choice to dry, it is a good idea to do another check on the orifice flange. Make sure there are no leaks or other complications with the orifice flange or orifice.

Step #9 Trim Excess Sealant or Adhesive

If you used a sealant or adhesive, wait for it to dry and then trim off any excess from around the orifice flange.

Step #10 Clean Orifice Flange or Orifice

Once the orifice flange or orifice has been installed and dried, clean it using a wire brush or high-pressure water nozzle to ensure that there is nothing left from the sealant or adhesive. Now the orifice flange or orifice should be properly installed and ready to use.

The installation process for orifice flanges is a relatively simple one, as long as all of the right measurements and precautions have been taken. When buying or buying replacement orifice flanges or orifices, always make sure that they will fit or function appropriately with whatever machinery or orifices you are using or installing them on.

4. Common Problems With Orifice Flanges and How to Solve Them

Orifice flanges are prone to certain problems that can affect their performance. Here are some of the most common issues and how to fix them:

Leaking or Faulty Seals

Leaking or faulty seals are the most common problem with orifice flanges. This can be caused by a variety of factors, such as improper installation or damage to the seals. To fix this issue, you will need to inspect the seals and replace them if necessary.

Incorrect Orifice Size

Incorrect orifice size is another common problem with orifice flanges. This can be caused by using the wrong orifice plate or by incorrectly measuring the orifice diameter. To fix this issue, the orifice size can be checked and adjusted if necessary.

Burrs or Obstructions on Orifice

Burrs or obstructions on orifice can also affect the performance of orifice flanges. This can be caused by a variety of factors, such as damage to the orifice plate or foreign objects getting caught in the orifice. Burrs or obstructions can be removed with a sharp object such as a razor or a pick.

Scratches or Signs of Wear and Tear

Orifice flanges can get scratched or worn out from use. If the scratches or marks are not very deep, they can be removed with fine sandpaper or steel wool. However, if there is damage to the metal, it may need to be replaced by a professional or a certified welder.

Therefore orifice flanges are prone to several problems, however, they can be easily fixed or replaced. By inspecting orifice flanges regularly, you can ensure their proper performance and safety for your facility or plant.

5. Proper Orifice Flange Maintenance

It is important to properly maintain orifice flanges to ensure efficient and safe operations. The following are a few tips for proper orifice flange maintenance:

| 1 | Keep Orifice Flanges Clean and Free of Debris |

| 2 | Inspect Orifice Flanges for Damage or Wear |

| 3 | Make Sure Orifice Flanges Are Properly Aligned and Fastened |

| 4 | Lubricate Orifice Flanges As Needed |

| 5 | Replace Orifice Flanges When Necessary |

Keep Orifice Flanges Clean and Free of Debris

One of the most important aspects of orifice flange maintenance is keeping the orifice flange clean and free of debris. This can be done by regularly cleaning the orifice flange with a soft cloth or brush.

If there is a build-up of debris on the orifice flange, it can cause the orifice flange to become clogged and may result in a decrease in efficiency or even a failure of the orifice flange.

Inspect Orifice Flanges for Damage or Wear

It is also important to inspect orifice flanges for damage or wear. Damage or wear can occur due to several factors, such as corrosion, high pressures, or impact. If damage or wear is found on the orifice flange, it should be repaired or replaced as soon as possible.

Damaged or worn orifice flanges can result in a decrease in efficiency or even a failure of the orifice flange.

Make Sure Orifice Flanges Are Properly Aligned and Fastened

It is also important to make sure that orifice flanges are properly aligned and fastened. This can be done by checking the alignment of the orifice flange and ensuring that it is properly bolted or clamped in place.

If there is any damage to the orifice flange or if the orifice flange is not properly aligned or fastened, it should be repaired or replaced as soon as possible.

Lubricate Orifice Flanges As Needed

It is also important to lubricate orifice flanges as required. The orifice flange should be lubricated regularly or whenever any of its components are replaced or removed. Lubricating the orifice flange provides critical protection against wear and damage caused by abrasion, corrosion, or impact.

Replace Orifice Flanges When Necessary

It is also important to replace orifice flanges when necessary. If an orifice flange is damaged or worn, it should be replaced as soon as possible. Additionally, if an orifice flange is no longer performing its intended function, it should be replaced.

Replacing orifice flanges helps to ensure that the orifice flange is performing its intended function and that the orifice flange is in good condition.

Overall, orifice flange maintenance can be important in ensuring orifice flange efficiency or even preventing orifice flange failure. This is especially true if orifice flanges are used frequently or under harsh conditions.

6. Orifice Flange Average Cost

The orifice flange average cost will depend on the type, size, and material or orifice flange you choose. An orifice flange is a flow-control device that helps to regulate the flow of gases or fluids through a pipe or duct.

To pick the right orifice flange for your needs, it’s important to understand orifice flange functions or orifice flange types.

Orifice Flanges are typically made from carbon or stainless steel or other metal alloys. Each has its orifice flange design with a specific orifice flange purpose in mind, so it’s important to know the orifice flange type and orifice flange sizes or orifice flange dimensions you need.

The orifice flange average cost can range anywhere from $50 to $200, depending on the size and type of orifice flange. It’s important to choose the right orifice flange for your needs, as this will ensure proper performance and avoid any potential issues.

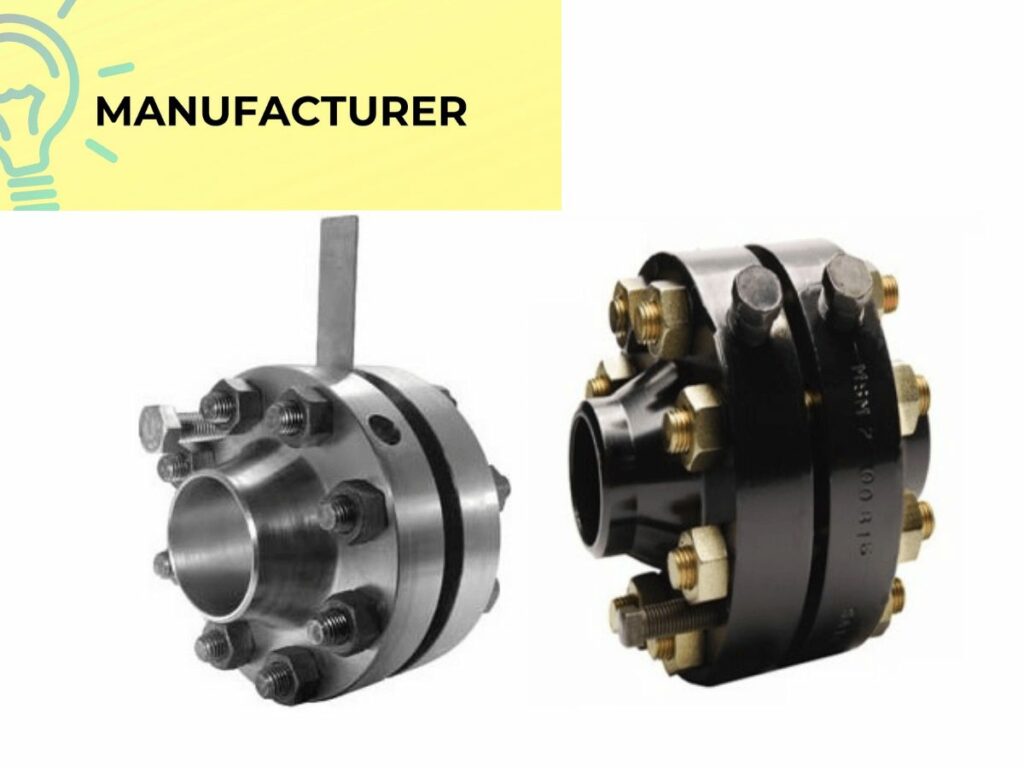

7. Orifice Flange Manufacturer

Orifice flanges are used in conjunction with orifices to measure or control the flow of fluids or gases. They are typically made from metal or plastic and come in a variety of sizes and styles. Orifice flanges are manufactured by several companies, including:

Hebei Xinyue

Hebei Xinyue is a manufacturer of orifice flanges. They offer a variety of products in a variety of sizes and styles to meet your needs. All orifice flanges are made from quality materials and are inspected for quality before they are shipped to you.

Xinyue orifice flanges are available in orifice flange tapping standard or special sizes. They are made from high-quality carbon steel or metal alloy, and they come with heat-treated faces, bushings (without or with lube groove), and raised parallel faces.

Rongxiang Valve Pipe

Rongxiang Valve Pipe is your best bet for finding quality orifice flanges at an affordable orifice flange price. They offer competitive pricing on all our products, including high-quality orifice flange lines.

Rongxiang team has over 20 years of experience manufacturing these parts, which means you’ll get top-notch quality every time you order from them. They ship orifice flanges worldwide, and they meet or exceed all the accepted quality standards of the industry.

Cangzhou Hengjia Pipeline Co., Ltd

Cangzhou Hengjia Pipeline Co., Ltd is also a quality orifice flange manufacturer. They offer competitive pricing and quality products. They have over 10 years of experience manufacturing orifice flanges and meet or exceed all the accepted quality standards of the industry.

Oflange

Oflange is an Orifice Flange Manufacturer that is based in China. They have Orifice Flanges that are made to be extremely durable and able to handle high heat. Oflange are used by many companies throughout the world.

These Orifice Flange Manufacturers are just a few of the companies that can produce Orifice Flanges. Contact any one of these companies directly for more information on their products and services.

8. 6 Tips to Choose the Right Orifice Flange for Your Needs

When it comes to orifice flanges, there are a few things you need to keep in mind to make sure you choose the right one for your needs. Here are some tips:

#1 Consider the Orifice Size

Make sure you know or can find out before buying your orifice flange what orifice flange weight or size it has. Knowing this will help you choose the right orifice flange for your needs and should also give you a good idea of how much gas or oil you will need to use through that orifice. Remember that orifice sizes are measured in units or as fractions of units of area.

#2 Consider Orifice Shape

You will also need to consider the orifice’s shape. Three common orifice shapes are round, square with flat sides, and triangular. The orifice’s shape determines how much gas or oil passes through it per minute or hour. Most orifice flanges come with orifices that are round or square, but you can also get orifice flanges with triangular orifices.

#3 Look for Orifice-Flange Specifications

When choosing an orifice flange, make sure it has a specification sheet attached to it so you know what to expect from the orifice or orifices it comes with. You should also know or be able to find out or ask about the orifice-flange class, which tells you how accurate or precise the orifice flange is at measuring gas flow.

#4 Look for the Right Material

When choosing an orifice flange, make sure it has the right or appropriate material for the orifices or orifice flange or orifice-flange class you’re after. Some materials used to make orifice flanges include carbon steel and stainless steel, although some other metals and alloys can be used as well.

#5 Look for Orifice Flange Standards

When choosing an orifice flange, make sure it meets or is made to at least one orifice flange standard. There are standards for orifice calibration and orifice flange class. Using oracle flanges that meet or exceed one or more of these standards can help you get results that are more accurate or precise or provide a more secure seal with less leakage.

#6 Look for Orifice-Flange Features

When choosing an orifice flange, make sure it has or comes with orifice flange features you need or want. Such features includeNPT threaded ends or a face seal that is flat or has an orifice flange face seal. This can help you get more results or benefits or provide a more secure or leak-proof seal.

By considering these tips, you should be able to find or buy the right oracle flange for your needs.

9. Conclusion

Orifice Flange is the perfect solution for connecting pipelines and other components in a fluid system. It provides a leak-free seal and easy installation, making it an essential part of any plumbing or piping system.

With Orifice Flange, you can rest assured that your pipeline will be sealed tightly and securely. It’s the perfect solution for connecting pipelines and other components in a fluid system.

Click here to purchase this product on our website!