PRODUCT FEATURES

Flange Class 150 Manufacturer to Rocket Your Business

PRODUCTS

Proud To Offer A Wide Variety Of Flanges

If you are looking for something specific that isn’t listed on our website yet, just contact us today!

ABOUT US

Who Is Oflange.com

oflange.com have seen that today there are also many flange companies in China & internationally. However, their solutions were still stuck a few years ago.

In fact, we have been upgraded in recent years, and oflange.com hope our smart and flexible solutions can inject fresh blood into this market.

PARTNER

Who Trust Us

BUYER’S GUIDE

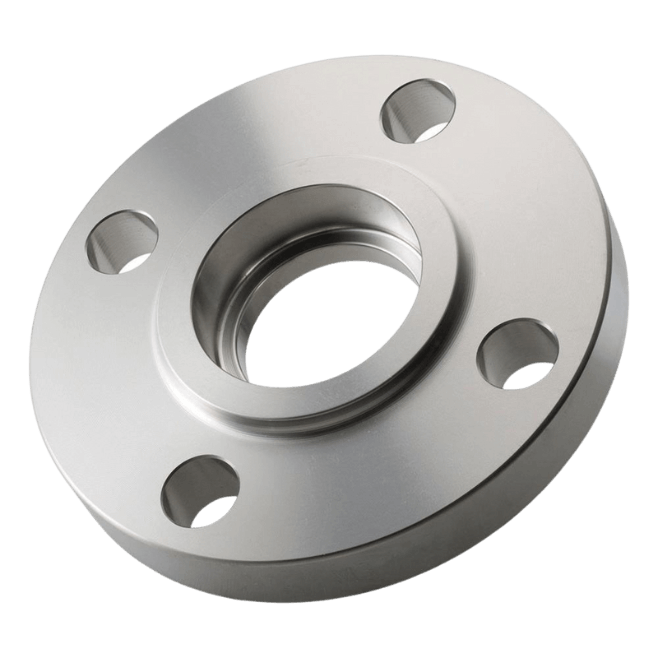

Flange Class 150

Flange Class 150 is perfect for use in a wide range of industries, from plumbing and HVAC to petrochemical and food processing. This flange class is made from carbon steel, so it is tough and reliable. It also has a weld neck design that makes it easy to install.

This material is ideal for water distribution systems or any application where corrosion resistance and durability are essential.

Flange Class 150 is a high-performance, lightweight and highly durable material that allows for easy installation in any type of piping system. The Flange Class 150 is available in three different sizes, ranging from 1/2″ to 4″, with an optional 3/4″ size.

Flange Class 150 is a flange designed to strengthen the flange and prevent its loosening from vibration, making it not easy to loosen. This flange class is designed for use with high-pressure systems, making it ideal for a variety of applications.

Table of contents

1. Flange Class 150 Definition and Its Uses

A flange class 150 is a type of flange that has a nominal pipe size of 150 millimeters or 6″. It is typically used in high-pressure and high-temperature applications.

Flange class 150 is a type of flange that is commonly used in many industries. It has a higher strength rating than flange class 125, making it ideal for use in more strenuous applications.

Additionally, flange class 150 is less susceptible to damage from high pressure or sudden impacts. This makes it a better choice for use in situations where durability is important.

Finally, flange class 150 is also more resistant to corrosion and degradation, making it a longer-lasting option.

Some common uses for flange class 150s include:

- Piping systems in the oil and gas industry

- Piping systems in the chemical industry

- Piping systems in the power generation industry

2. The Different Types of Flanges Class 150

Here are the different types of flange class 150.

Weld Neck Flange

A weld neck flange is a type of flange that is used to connect two pieces of pipe. The flange is attached to the end of one pipe, and the other pipe is then inserted into the flange. A weld is then performed around the circumference of the flange, which connects the two pipes.

Threaded Flange

Threaded flanges, also known as companion flanges, screw flanges, or NPT flanges, have a female NPT thread in the middle that allows them to connect to male NPT threaded piping. When making reducing connections, threaded flanges are commonly used.

Slip On Flange

A slip-on flange, also known as SO flange, is a type of flange that attaches to the end of a pipe. It is typically made from forged steel and has a hub on one side and a face on the other. The face of the SO flange has machined threads that mate with the threaded ends of pipes.

Lap Joint Flange

A flange is a type of connector used to join two pieces of pipe. Lap joint flanges are usually made from cast iron or forged steel pipe flanges and have a raised face diameter of 2.5″. The flanges are bolted together and the gasket is sandwiched between the flanges.

Socket Weld Flange

A socket weld flange is a type of flange that is used to connect two pipes. It is typically a flat disc with a hole in the middle that allows it to be bolted onto the end of one pipe. The flange then seals against the surface of the other pipe, creating a watertight seal.

Blind Flange

A blind flange is a type of flange that is used to seal the end of a pipe. It does not have any holes in it, so it cannot be used to regulate the flow of fluid through the pipe.

3. Flange Class 150 Ratings

In flange engineering, flange class 150 ratings are used to denote the number of PSI that a flange can hold. A flange with a rating of 150 is generally considered a nominal flange for pressure service in pipe flanges.

Pressure rating is defined by flange class. A flange is a technical device used to create the seal between two flanged components, such as pipe flanges or flanged aluminum extrusions. The flange ensures that no gases or fluids escape where they are not meant to go.

The pressure rating for flanges, in general, goes up to flange class 600, which is the highest flange class. Usually, flanges with flange class below 150 are used for low-pressure applications like household gas flanges.

However, flange class ratings above 150 should be taken seriously because flanges with flange class ratings above 150 are usually used in high-pressure industries such as oil and gas applications. A flange should never fail under pressure, especially those with a flange class rating of 150 or more, should be taken seriously.

4. Flange Class 150 Dimensions

Flange Class 150 Dimensions

A flange class 150 is a type of flange that has a nominal diameter of 150 millimeters. It is also known as a flange size 150. This type of flange is typically used in high-pressure applications. The flange class 150 dimensions and specifications are as follows:

Here are the dimension of a ANSI/ASME b16.5 class 150 flange (dimensions are in inches):

- bore: 2.875″

- outside diameter: 6.625″

- hub diameter: 3.5″

- bolt circle diameter: 5.5″

- thickness: 0.25″

- width: 3.5″

- bolt holes: 4.0″

- bolts diameter: 1.125″

Nominal pipe size (NPS) is the size of pipe at which the flange is designed. Here are some of the pipe size.

- 2″

- 8″

- 12″

- 16″

- 24″

5. Ways on How to Identify a Flange Class 150

When looking to purchase a flange class 150, you must be able to identify it properly. There are a few ways that you can do this.

Look at the Flange Itself

Flanges come in different shapes and sizes, so you’ll want to make sure you are looking at the right one. Class 150 flanges have a smooth, round shape and are typically made from steel.

Check the Flange Dimensions

Each flange class has specific dimensions that set it apart from the others. Class 150 flanges have an inside diameter of 2.375″, an outside diameter (flange od) 6.6″ and a thickness of 0.25″.

Check the Flange Rating

The flange rating is a measure of how much pressure the flange can withstand. A class 150 flange can handle up to 150 pounds per square inch of pressure.

Look For the ANSI Stamp

All flanges manufactured in the United States must meet the ANSI (American National Standards Institute) standards. If the flange is certified, it will have a stamp on it that reads “ANSI.”

6. The Benefits of Using a Flange Class 150

Here are the benefits of using a flange class 150.

| 1 | Durable Flange With Better Performance |

| 2 | Weight Flexibility |

| 3 | Less Vibration |

| 4 | More Stable flange |

| 5 | Reliable Flange |

| 6 | Less Maintenance |

Durable Flange With Better Performance

A flange class 150 is made from steel which means it is a sturdy flange. It has been tested to perform well with most types of equipment. This flange also has a smooth surface that will make it easier for you to weld.

Weight Flexibility

A flange class 150’s approximate weight is around 10 pounds. This makes it easier to install when you are working alone. You can easily carry this flange with the rest of your equipment without having to ask for help from an additional person.

Less Vibration

With flange class 150 flanges, you can expect less vibration because of their design. This flange class has a small diameter as well as rough edges making it easier for them to slide through equipment without creating too much noise or disturbance.

More Stable flange

A flange class 150 is more stable which makes it easier for you to attach your equipment with no problems at all. You won’t have any difficulties when using this flange since it can easily fit into the flanges of other materials that are used most often.

Reliable Flange

A flange class 150 flange is easy to use and reliable because of its design. This flange has an extra thick flange that can perform under stress without worrying about it getting broken by the equipment. This flange will also help you save time since it can be used with other flanges that are made from the same materials.

Less Maintenance

You can expect flange class 150 flanges to need less maintenance. This flange is designed so that it can last long without being damaged by most types of equipment. This flange will help you save on labor since you do not have to spend a lot of time trying to fix this flange or replace it altogether.

7. Process of Installing a Flange Class 150

Here is a step by step guide on how to install a flange class 150.

Step #1 Clean Flange And Surface Area Before Installation

The flange should be free of all dirt, oil, grease and rust. Also, ensure that the mounting surface is smooth and flat.

Step #2 Check Flange For Damage

Check flange for any visible damage or defects to make sure it is safe to use.

Step #3 Install Flange on Equipment

Install flange on your machinery. Do not tighten the flange yet.

Step #4 Adjust Flange For High Pressure

Make sure the flange is in line with equipment to avoid contact when under pressure.

Step #5 Tighten Flange

Tighten the flang securely to ensure it does not come off during use. Make sure the flange is still in alignment with machinery.

Step #6 Check Flange for Damages

After installing flanges, make sure to check flanges for any damage to avoid potential damage during use.

8. Manufacturing Process of Flange Class 150

Here is a step by step guide on how flange class 150 flanges are made:

Step #1 Cutting of Raw Materials

The flange is manufactured using several different materials. It can be made of steel, cast iron or ductile iron. The flange needs to be flame cut according to the manufacturer’s specifications before it is machined and welded together with other parts of flange assembly.

Step #2 Heating in High Temperature

The flange needs to be heated at high temperature. The flange must be consistent and uniform surface finished during this process as it will help keep flange from leaking under pressure.

Step #3 Forging

The flange is forged in a press. This will help to achieve the desired shape and size for the flange.

Step #4 Machining

The flange is then machined using CNC machines. The holes are drilled and the flange is precision-machined to ensure that it has right shape and size for flange to perform its function effectively.

Step #5 Welding

The flange is welded together with other parts of flange assembly using the TIG welding process. This will help to achieve the desired strength and durability for the flange.

Step #6 Testing

The flange is then tested for leaks and other defects before it is sent to the customer. It is important to test the flange under pressure to ensure that it meets the requirements.

Step #7 Packaging and Delivery of the Flange

The flange is then packaged and delivered to the customer. It is important to note that flanges are heavy and bulky, so they will require a lot of space during transportation.

9. Flange Class 150 Average Price

The average price of a flange class 150 ranges from USD 50 to USD 100 per flange. This is a relatively low price point, which can make them an attractive option for many buyers. The flange class 150 is made of mild steel and can be powder coated or painted.

With the possibility of buying bulk flange class 150 flanges, a larger business may be able to save a couple of bucks on the flanges. Purchasing flange class 150 flanges from a major manufacturer may allow buyers to have flanges that fit their needs and fit into industry standards of design and reliability.

10. 6 Tips to Choose the Right Flange Class 150 for Your Needs

Here are a few tips on how to choose the right flange class 150 for your needs.

#1 Make Sure That it Fits Your Budget

The flange class 150 flange is available at several online stores. An average flange class 150 flange costs USD 150 to USD 300.

#2 Make Sure That it is the Right Material and Design For You

For flanges that are used in industry, make sure to choose flange class 150 flanges that match industry standards. There are flange class 150 flanges that are made of nickel alloy. Make sure to choose flange class 150 flanges that can withstand heavy-duty use while being cost-effective.

#3 Check Quality Through Reviews

Before making a purchase, always check the quality of flange class 150 flanges by reading customer reviews. This will give you an idea of what to expect and whether or not the flange class 150 flange is worth your investment.

#4 Check Quality With Manufacturer’s Warranty

Most flange class 150 come with a manufacturer’s warranty. Make sure to check the terms of the warranty before making your purchase. This will give you peace of mind in case something goes wrong with the flange after you’ve bought it.

#5 Do Additional Research

It is not enough to simply do flange class 150 flange reviews. There are many flanges on the flange market. Therefore, make sure to research flanges that you are interested in before finalizing your decision on flanges that best fit your needs.

#6 Choose Reputable Manufacturers and Distributors

Flanges manufacturers and distributors that have been in the flanges business for a long time such as Oflange may be able to provide quality flanges and trust to their customers.

11. 6 Tips for Installing and Using a Flange Class 150 Safely and Effectively

Here are some tips for installing and using a flange class 150 safely and effectively.

#1 Read the Instructions Carefully

Manufacturers of flanges carry instructions on how to safely use flanges. These instructions include flange installation, use and maintenance instructions. Make sure to read these instructions carefully before installing or using flanges.

#2 Use the Correct Tools

To correctly install flanges, it is important to use the correct tools. Incorrect installation of flanges can lead to damage and leaks. The following are some of the tools that are necessary for flange installation: flange wrenches, flange spreaders, flange bolts and nuts.

#3 Check for Leaks

When flanging flanges, make sure to check flange for leaks after installing. Checking for leaks will not only save on costly repairs but also prevent flanges from blowing out and causing damage elsewhere.

#4 Use Lubricant When Installing

Using lubricant when flanging prevents it from scratching flange surfaces. Flanger lubricants come in several viscosities to match each flanged material. For more metallic materials, use a thinner lubricant. For more abrasive materials, use a thicker lubricant.

#5 Don’t Overtighten Flanges

Flanges should not be overtightened as this can lead to flange failure. Over tightening flanges can cause the flanges to warp and eventually break. When installing flanges, use the correct torque to avoid over-tightening flanges.

#6 Avoid Contact with Other Surfaces

When flanging flanges, it is important to avoid contact between flanges and other surfaces. This will prevent the flange from being scratched or marked. It is also important to avoid contact between flanges and other materials as this can cause the flange to deform.

To know more about the differences between flange classes, watch this video.

12. Conclusion

This flange class is designed for use with systems under high pressure and is ideal for a variety of applications. Industries like plumbing, HVAC, petrochemical processing, and food production rely on Class 150 flanges to keep things running smoothly.

If you are looking for a flange class that can handle high pressure, Class 150 is the perfect option. Contact us today at Oflange to learn more about our products and how we can help you meet your needs.