PRODUCT FEATURES

ALL HAND TOOLS & POWER TOOLS

PRODUCTS

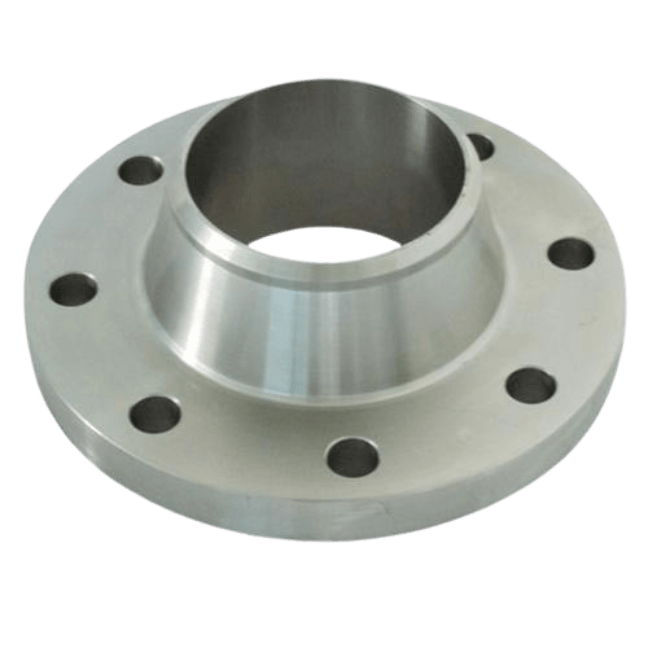

Proud To Offer A Wide Variety Of Flanges

If you are looking for something specific that isn’t listed on our website yet, just contact us today!

ABOUT US

Who Is Oflange.com

oflange.com have seen that today there are also many flange companies in China & internationally. However, their solutions were still stuck a few years ago.

In fact, we have been upgraded in recent years, and oflange.com hope our smart and flexible solutions can inject fresh blood into this market.

PARTNER

Who Trust Us

BUYER’S GUIDE

ASME Flange: ANSI B16.5 Standard

ANSI B16.5 is the standard for ASME flanges, which are commonly used in the oil and gas industry. These flanges are available in several sizes and pressure ratings. They are also easy to install and have high corrosion resistance. In addition, ASME flanges have a lower cost of ownership than other types of flanges.

ASME flanges are good for projects that have a lot of vibration, are exposed to corrosive materials, operate at high temperatures, and require frequent maintenance or replacement of parts. ASME flanges can help reduce downtime in your operations.

If you are looking for a reliable and cost-effective flange option for your next project, consider using ASME flanges. You can be confident that they will meet your needs and exceed your expectations.

Table of contents

1. Applications of ASME Flange

ASME flanges are used in a variety of applications across various industries. Some of the most common applications include:

Piping Systems

ASME flanges are commonly used in piping systems. They provide a connection between two pipes and can be used to change the direction of the pipe flanges, as well as to join two pipes of different sizes.

Process System

Process systems are an important part of many industrial and commercial applications. They can be used to control and monitor a variety of processes, from manufacturing to water treatment. ASME flanges are a common type of flange that is often used in process systems.

They are made from high-quality materials and are designed to withstand the high pressures and temperatures that are often found in these applications.

Shipbuilding

ASME flanges are a critical part of the shipbuilding process. Flanges connect different parts of the ship and must be made with the utmost precision and care. ASME flanges are made to the highest ASME standard for flanges, ensuring that ships are built safely and efficiently.

2. Cost of ASME Flange

When it comes to the cost of an ASME flange, there are a few factors that will impact the price. The size, material, and type of flange all play a role in how much it will cost. In addition, the company that you buy from may also charge additional fees, such as shipping and handling.

That said, the average cost of an ASME flange class ranges from USD 50 to USD 200. The size and material of the flange are the two biggest factors that influence the price. For example, a stainless steel flange will be more expensive than a carbon steel flange. And a larger flange will cost more than a smaller one.

3. ASME Flange Dimensions

ASME flange dimensions are standardized and listed in the ASME B16.47 Standards. This document covers a variety of topics related to ASME flanges, including dimensions, ratings, and materials. The most common ASME flange dimensions are as follows:

The Size of the Flange

The size of the flange is measured in inches. The most common sizes are between ½ inches and 24 inches. The size of the flange will affect the thickness and number of bolts that are required.

The Thickness of the Flange

The thickness of the flange is measured in inches and ranges from ¼ inches to 12 inches. The wall thickness of the flange affects its strength and durability of the flange. It is important to select a thickness that is appropriate for the application.

The Number of Bolts

The number of bolts required for a flange depends on the size and thickness of the flange. Generally, the number of bolts ranges from 4 to 24. The bolts play an important role in securing the flange to the pipe.

The Bolt Circle Diameter

The bolt circle diameter is the diameter of the circle that the bolts make when they are all tightened down. The most common bolt circle diameters are between ⅝ inches and 12 inches.

The dimensions of an ASME flange can vary depending on the type of flange and the application. However, the dimensions listed above are some of the most common.

Here at Oflange we are a leading manufacturing company that produces ASME ANSI B16.47 Series A and B Flanges, B16.5 flange, as well as other types of pipe fittings. Contact us for more information!

4. How To Determine What the Type of ASME Flange Should I Use

If you’re not sure what type of ASME flange to use, there are a few things you can do to determine the best option. By far the best way to determine the type of flange is to consult with an engineer or someone familiar with ASME flanges. They will be able to help you select the right flange for your application.

In addition, there are a few guidelines that can help you decide which type of ASME flange to use:

Identify the Type of Flange Service

The first step is to identify the type of service that the flange will be used for. This can be done by consulting the ASME B16.47 Standard. The standard defines a variety of services, including common applications and industries.

Choose an ASME Flange Type Needed

There are a few different types of ASME flanges, so it’s important to choose the right one for your application. Some of the most common types of ASME flanges include slip-on flanges, socket ASME weld neck flange dimensions, and blind flanges.

Check the Dimension

Once you’ve determined the type of ASME flange you need, make sure to check the ASME pipe flange dimensions to make sure they match your application. The flange dimensions will vary depending on the type of flange you choose.

Contact an Expert for Professional Opinion

If you’re still not sure which ASME flange to use, contact qualified mechanical engineers for assistance. They can help you select the right flange for your specific application and ensure that it meets all of the requirements.

5. How Do ASME Flanges Are Being Classified?

There are a few different ways that ASME flanges are classified. It can be easily done by following the ASME B16.47 Standard. Here are some of the most common ways that ASME flanges are classified:

Material of the Flanges

Flanges are made from a variety of materials, including carbon steel, stainless steel, and alloy steel pipe flanges. The type of material used affects the flange’s properties, including its strength and resistance to corrosion.

The Shape of the Flange

Flanges also come in a variety of shapes, including round, square, and rectangular. The shape of the flange affects its strength and how easily it can be installed.

Size of the Flange

Flanges also come in a variety of sizes. ASME flange sizes determine the maximum pressure that it can withstand. It also affects the size of the hole that needs to be drilled to install the flange. The ASME flange bolt holes sizes must be correct.

By understanding how ASME flanges are classified, you can select the right flange for your application. Consult with a qualified engineer if you have any questions about which type of flange is best for your project.

| Classification | Description |

|---|---|

| Material of the Flanges | Flanges are made from a variety of materials, including carbon steel, stainless steel, and alloy steel pipe flanges. |

| The Shape of the Flange | Flanges also come in a variety of shapes, including round, square, and rectangular. The shape of the flange affects its strength and how easily it can be installed. |

| Size of the Flange | Flanges also come in a variety of sizes. ASME flange sizes determine the maximum pressure that it can withstand. |

6. 3 Tips for Maintaining ASME Flanges To Ensure Longevity and Proper Function

ASME flanges are an important part of many piping systems, and it’s important to take steps to ensure they remain in good condition and function properly. Here are a few tips for maintaining ASME flanges:

#1 Make Sure the Gaskets and Bolts Are in Good Condition

Maintaining ASME flanges is important to ensure longevity and proper function. One key way to maintain ASME flanges is to make sure the gaskets and bolts are in good condition and properly tightened.

Gaskets should be replaced when they are worn or damaged, and bolts should be tightened to the correct specifications. If the gaskets or bolts are not in good condition, it can cause the ASME flange to leak or fail.

#2 Keep the Flange Area Clean and Free of Debris

If you want to ensure that your ASME flanges continue to work properly for as long as possible, it’s important to keep the flange area clean and free of debris. This will help to prevent any damage or interference with the proper function of the large-diameter steel flanges.

Additionally, keeping the flange area clean will help to maintain the appearance of your equipment.

#3 Avoid Using Excessive Force When Tightening Bolts

When tightening the bolts on an ASME flange, it’s important to use the correct amount of force. Excessive force can damage the flange and interfere with its proper function. It’s best to tighten the bolts gradually, applying just enough force to achieve a snug fit.

By following these tips, you can help to ensure that your ASME flanges remain in good condition and continue to function properly.

7. Common Problems That Can Occur With ASME Flanges and How To Fix Them

The ASME B16.47 flange is a type of flange that is commonly used in many industries. However, as with any type of equipment, there can be problems that occur. We will discuss some of the most common problems that can occur with ASME flanges, as well as how to fix them.

Leakage

One of the most common problems with ASME flanges is leakage. This can often be caused by a lack of sealant or improper installation. If you are experiencing leakage, it is important to correct the issue as soon as possible, as it can lead to other problems down the line.

Damage to the Gasket

Another common problem with ASME flanges is damage to the gasket. This can be caused by several things, including pressure changes within the system as well as improper installation.

If you are experiencing damage to your gasket, it is important to have this repaired as soon as possible. Doing so will help prevent further damage from occurring in the future.

Corrosion on the Surface Area

A third common problem with ASME flanges is corrosion buildup on their surface area. This can often be caused by a lack of maintenance or improper installation. If you are experiencing corrosion buildup on your flanges, it is important to have them cleaned and treated as soon as possible.

Misalignment of ASME Flanges

Finally, another common problem with ASME flanges is misalignment. This can often be caused by incorrect installation or wear and tear over time. If you are experiencing misalignment, it is important to have it corrected as soon as possible. Doing so can help prevent further damage from occurring.

If you are experiencing any of these common problems with your ASME flanges, be sure to take action as soon as possible. By doing so, you can help ensure that your system continues to run as smoothly as possible.

8. Benefits of Using ASME Flanges

When it comes to using ASME flanges, several benefits come along with it. The main benefits of using ASME flanges in these applications include:

Increased Safety and Reliability

Perhaps the most important benefit is the increased safety and reliability that it provides. ASME flanges are designed and tested to meet specific standards, which helps to ensure that they will function as intended. This can help reduce the risk of accidents and failures in your system.

Reduced Maintenance and Operating Costs

Another key benefit of using ASME flanges is that it can help reduce maintenance and operating costs. ASME flanges are often made from higher quality materials, which can help to extend their life span. Additionally, they are often easier to maintain and less likely to experience problems.

Improved Product Quality

Using ASME flanges can also help improve product quality. This is because ASME flanges are often designed and manufactured to tighter tolerances than other types of flanges. This can help to ensure that your product meets or exceeds the required specifications.

Longer Lifespan

ASME flanges have a longer lifespan as compared to other types of flanges. This is because they are made from high-quality materials and are subjected to rigorous testing. They also conform to the ASME Boiler and Pressure Vessel Code, which ensures that they meet the highest standards of quality.

Reduced Downtime

When it comes to reducing downtime, ASME flanges are a key player. By using ASME flanges in your piping system, you can minimize the number of potential failure points in your system.

This means that when there is a problem with one ASME flange, it will not cause the entire system to go down. Instead, only the impacted portion of the system will be affected. This can help to reduce overall downtime and keep your business running smoothly.

High Pressure Class Rating

ASME flanges are also able to handle higher pressure temperature ratings as compared to other types of flanges. This can be a key advantage in systems that require a high-pressure operation.

When it comes to choosing a flange for your system, it is important to select one that meets the specific requirements of your application. By using ASME flanges, you can help ensure that your system remains safe and reliable while also reducing maintenance and operating costs.

To know more about the use of ASME flange, check out this video.

9. Final Words

ASME flanges are the best option for many industrial applications. They are made of high-quality materials, have a variety of sizes and pressure ratings, and are easy to install. In addition, they have a low cost of ownership.

ASME flanges are perfect for projects that have a lot of vibration, are exposed to corrosive materials, operate at high temperatures, or require frequent maintenance or replacement of parts. They can help reduce downtime in your operations.

If you have any questions or clarifications, be sure to contact us at Oflange. We would be happy to assist you!